Optimum humidity for the production of

concrete elements

Humidity plays an important role in the production of concrete components for achieving the best results. Is the air too dry, it leads to an excessive evaporation of water above the fresh concrete surface. In the following article, Andrej Arnold

(Condair) gives more detailed information on the possibilities of modern humidifiers.

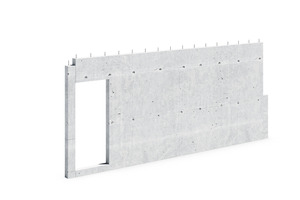

Humidity plays an important role in the production of concrete components for achieving best results. Is the air too dry in the production hall or in the curing chamber, it leads to an excessive evaporation of water above the fresh concrete surface. This can entail a number of defects. Modern humidifiers prevent this effectively, thus being a decisive factor for ensuring the concrete quality.

Concrete must have a sufficient density so as to be able to meet all requirements in terms of durability. The lower porosity and permeability are, the more resistant concrete products are to external influences later. The quality of precast concrete elements is decisively dependent on the concrete hardening process. Therefore, attention should be paid to a few things, depending on the concrete mix design, regarding the duration and procedure of this process as well as in the curing process during the first days. Hence, for example, the outdoor temperature and/or room temperature, the processing temperature and the humidity have an influence on the concrete quality.

The strength development begins already when the fresh concrete is setting, immediately after pouring into the formwork and when being compacted. Setting is accompanied with the evaporation of the excessive mixing water and the concrete begins to shrink simultaneously. To prevent excessive evaporation, concrete curing must take place early and over a sufficiently long time. In this way, above all, the density in the concrete boundary zone is ensured and early shrinkage cracks can be avoided.

Protection against drying too quickly

The curing process is an important aspect in the production of concrete. It decisively provides for the durability of concrete components. A key objective is to ensure that there is sufficient water in the near-surface areas of the concrete for cement hydration. If the humidity is too low, the concrete dries too fast.

Depending on the shape and size of the concrete component, various measures – being partially outdated – are used in the production of concrete in order to avoid premature drying:

covering with sheeting,

covering with water-retaining sheets,

continuous water spraying,

storing under water,

leaving in the formwork.

These traditional methods are cost- and labor-intensive and frequently do not result in the desired success. By using modern equipment for room humidification, the premature drying of concrete surfaces can be avoided much more effectively.

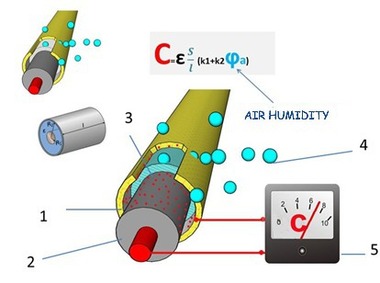

Evaporation, humidity and vapor pressure

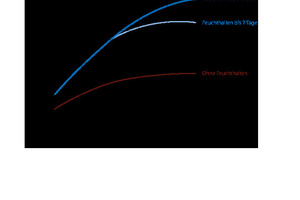

During hardening of the fresh concrete, the concrete is releasing the mixing water, that is not required, back into the environment by evaporation. The evaporated water generates a certain vapor pressure higher than that of the ambient air. In order to compensate this vapor pressure gradient, the ambient air continuously extracts moisture from the concrete element. This leads to a reduction of the volume, namely to a contraction or compression of the structural member, which may cause cracks.

By increasing the humidity, the gradient between vapor pressure in the concrete and that of the air can be equalized systematically, thus avoiding the above-mentioned disadvantages.

Modern humidification technology for perfect concrete quality

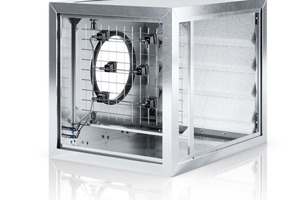

In case of an adiabatic air humidification using liquid and treated water, the dry and mostly cool air must be warmed, before being humidified. Modern adiabatic humidification systems use preheating registers for this purpose. Afterwards, humidification continues until the requested supply air humidity and supply air temperature is reached, respectively. An enthalpy control system is used here as a suitable control method. This allows for a coordinated regulation of the required performance of the heating register and humi-

dification. The electrical energy expenditure for the operation of humidification pumps is very low in case of low pressure and the use of low-energy pumps.

For steam humidifiers, on contrary, the heat for the generation of steam is supplied by electricity or natural gas. On the other hand, in comparison to humidification with water, no additional heating of the air stream is required because no cooling takes place as a result of the humidification process.

Another advantage is the fact that the humidifi-cation with steam is safe in terms of hygiene. Which humidification method achieves the best results is always dependent on the individual case. Both methods, the steam humidification and the adiabatic humidification demonstrate their strengths in different ways depending on the requirements.

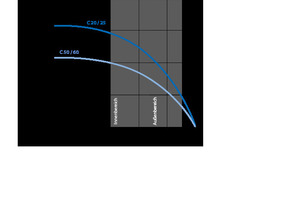

The following distinction can serve as a simple guide for orientation, whereas neither being general exclusion criteria for one or the other method:

Adibatic humidifiers / hybrid humidifiers:

high up to very high humidification performance,

medium up to high requirements on the control accuracy,

indirect evaporative cooling.

Electric steam humidification:

low up to medium humidification performance,

high up to very high requirements on the control accuracy,

simple retrofitting.

Steam humidifiers for existing steam:

low up to very high humidification performance,

high up to very high requirements on the control accuracy,

pressure steam network available.