Concrete monitoring system for the precast production

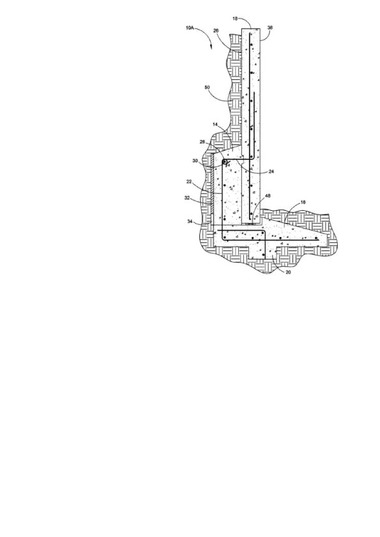

Hentschke Bau GmbH is a medium-sized construction company with a focus on the construction of motorways, roads and railway bridges. In the company’s own pre-fabricated concrete component plant in Bautzen, Hentschke Bau GmbH also produces demanding concrete components for structural and civil engineering, as well as individual pre-fabricated concrete component solutions.

Quick formwork dismantling

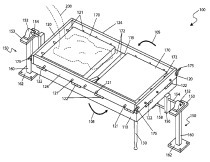

The central challenges for a pre-fabrication plant are primarily the high requirements on product quality and the fast production cycles needed to achieve a high level of productivity. It is therefore very important to plan the curing process efficiently. Being able to dismantle the formwork for the concrete components at the right time can increase productivity and, at the same time, achieve an outstanding level of quality.

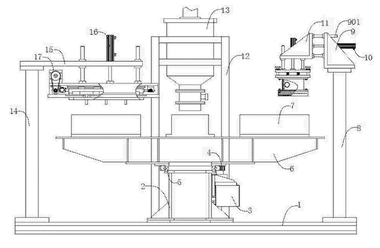

Hentschke Bau GmbH wanted to introduce a concrete monitoring system in order to optimize the manufacturing process for concrete components. After intensive research, the new Paschal customer decided upon Paschal Maturix, one of the best products for concrete monitoring on the market, according to the supplier. The system meets all of the important requirements for it to be able to be used successfully in companies. As Paschal Maturix has been intensively and successfully tested, Hentschke Bau GmbH has already equipped itself with several measurement system sets.

Processes can be optimised thanks to precise concrete curing times

Using an intelligent monitoring system such as Paschal Maturix, it is possible to dismantle formwork more quickly and ensure that the required strengths and dismantling deadlines can be complied with.

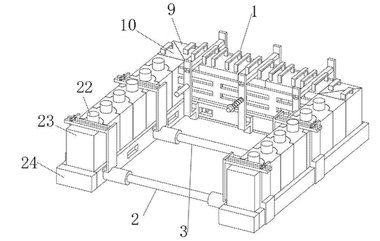

The accompanying Maturix software monitors the curing process of every concrete element and provides an overview of all relevant parameters of the concrete curing process. The Hentschke team thus obtains a real-time insight into the actual temperature, level of maturity and strength development of every concrete component via Paschal Maturix and can therefore precisely plan and optimise the work processes based on these data.

Ongoing collaboration planned with the Maturix team

As Hentschke Bau GmbH is so impressed with Paschal Maturix, it is planning to work with the Maturix team to promote the concrete monitoring system. Ideas as to how the system can be optimised and how smart technologies can be further promoted in the construction industry are already being developed.

CONTACT

Paschal-Werk G. Maier GmbH

Kreuzbühlstr. 5

77790 Steinach/Germany

+49 7832 71 237