Carbon Concrete Days: Step by step to market maturity

“CUBE” – this is the name of the building which will be used to implement the findings from research and development in the field of carbon- and textile-reinforced concrete over the past years and where they should come alive. Starting from the fall of 2019, the building, the first one made of carbon-reinforced concrete all over the world, is to be built on a plot situated at Zellescher Weg in Dresden, about 4 km of linear distance south of the Frauenkirche church and still within walking distance from the Faculty of Civil Engineering of the technical university.

In his closing lecture, Prof. Dr.-Ing. Dr.-Ing. E. h. Manfred Curbach, Director of the Institute of Concrete Structures at TU Dresden and chairman of the board of C3 – Carbon Concrete Composite e. V., organizing together with the Tudalit Association this year’s and the already tenth Carbon Concrete Days in Dresden, presented the “CUBE” building to the participants.

The building with the striking, multi-curved roof, that is called “twist”, will cover a gross floor space of 220 m². It will accommodate laboratories and presentation rooms. Structural components and connection systems are developed for the construction of the building and, at the same time, to make them ready for the market later, with their use being in compliance with the requirements of tender specifications, cost estimates, quality standards, material parameters, calculation and design methods.

However, research and development activities will not stop at all after the inauguration scheduled for spring 2021. During the planned ten years of building operation, all development results of the C3 project will be validated in long-term studies.

Economic challenges in mind

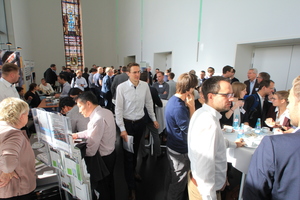

After intensive research work over the past decades, carbon- and textile-reinforced concretes are noticeably searching their way to the market now. This fact became also obvious to the more than 300 participants when reading the lecture program of the carbon and textile concrete days which took place this year on 25th and 26th of September at the Hygiene-Museum in Dresden.

The lectures, among others, dealt with the market potential and market prospects of products made of carbon- and textile-reinforced concrete. In the near future, a sub-project in the context of the C³ research project is to gather exemplary information on the extent to which the requirements for an economic production and an economic application of carbon-reinforced concrete do exist already and what challenges have to be met on the way to an appropriate production and use correspondingly. A first step will use a standardized wall – one made of steel-reinforced concrete and another made of carbon-reinforced concrete – as an example to determine which are the differences in their production and use, and which are the resulting cost differences. The detailed comparison shall reveal the stages of the value-added chain of carbon-reinforced concrete where comparatively high cost disadvantages might still exist.

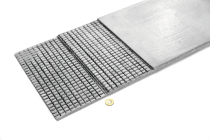

At present, the relatively expensive carbon reinforcement still appears to be a detrimental cost factor. However, contributions of scientists among the audience of this year’s carbon concrete days gave rise to the anticipation that alternative production methods are developed actively and obviously with success, using lignin, for instance.

Other lectures presented products of the supply industry that have almost been developed to market maturity. According to the scientists, these products will be urgently needed in the future production of structural components made of carbon- and textile-reinforced concrete because they are either not yet available or the currently used versions of the supplied parts are not suited for the use in the products made of carbon- and textile-reinforced concrete.

Well-attended accompanying exhibition

This year again, the lecture event was accompanied by an exhibition of the supply industry. A total of fourteen companies and organizations presented their products and services in the field of carbon and textile reinforcement on tabletop display stands. The list of exhibitors included, among others, the manufacturer of reinforcement, V. Fraas Solutions in Textile based in Helmbrechts, Solidian GmbH based in Albstadt, Hitexbau based in Augsburg, and Thyssenkrupp’s Kesseldorf location as well as Sika, Koch GmbH and CarboCon.

The next Carbon Concrete Days will be held on 24th and 25th of September of 2019 and will again take place at the Hygiene Museum in Dresden.

Text: Christian Jahn, M. A.