BIM/CAD/ERP solution for all areas of the precast plant

Whereas machines have mainly been responsible until now for increases in productivity and quality, software is currently the driving force. Comprehensive BIM/CAD/ERP solutions can help a company to achieve the decisive competitive advantage in the market. But which solution is really useful – and for whom?

The world is facing the next industrial revolution. The construction and precast industry is not immune to the automation of production and manufacturing processes. The question of how to realign a company and prepare it for the forthcoming changes is therefore more important than ever.

One thing is certain here – the key to the implementation of the new requirements lies in modern software solutions. Whereas hardware components such as production machines and robots have been the main tools for increases in productivity and quality in the past two decades, it is now software that is the driving force.

BIM – modern methods of project planning

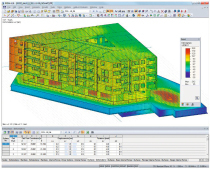

One example of this is BIM (Building Information Modeling). This process designates a method which, based on a 3D building model and with the corresponding software, enables the fully digitized and integrated planning and implementation of construction projects for everyone involved in the project. The big advantages of BIM for construction projects lie in the linking of all project participants to a central, graphic database, the real-time processing and provision of data and a continuously updated target/actual analysis option.

A construction project conducted in accordance with BIM specifications offers much greater security in terms of adherence to schedules, budget and cost monitoring and the coordination of the different trades. Through the direct nesting of all project participants specified by BIM as well as the use of the corresponding software, the actual project planning is transferred from man to the software. In the BIM project, man changes from the executive factor to the controlling factor, which reduces errors and optimizes the project coordination.

For whom is BIM worthwhile?

Of course, it would be nice to be able to realize the advantages of a BIM implementation described above in your own company just as a side project. Unfortunately, that‘s not possible, since such an implementation usually entails large-scale changes to internal project procedures in addition to the software equipment. Such a changeover is always associated with investment and the expenditure of time. Therefore, it is important in the first step to establish whether or not the changeover to BIM in your own company makes sense.

To do this, attention should be paid first of all to the type of projects in which the company is usually involved. Today, larger construction projects are often implemented on the basis of BIM and contracts are only awarded to companies who are technically prepared for participation in BIM processes. Also, numerous government authorities all over the world have already made BIM a condition for participation in public-sector construction projects in their countries. Therefore, those who wish to be involved in such projects in future would do well to consider BIM sooner rather than later. The other example would be precast concrete element manufacturers who deliver exclusively to private buyers (basement construction, garages, etc.). It would need to be clarified in each case here whether the introduction of BIM makes sense.

Necessary investments for the introduction of BIM

The most important decision is the selection of the right BIM program. It must be said here that the market has actually already made this decision. Since BIM projects are usually initiated and defined by the executive clients or project coordinators, the trades involved must for their part ensure that their software environment can communicate with that of the client. In the ideal case this is ensured by working on the same software platform as the client. Worldwide, the overwhelming majority of BIM construction projects are currently implemented using the Revit program from Autodesk. This program is the absolute market leader and a BIM solution based on Revit is the best choice for just about every precast plant. The exchange of data with other BIM solutions is basically possible via the IFC interface; however, every interface in the data stream represents a potential source of error and should be avoided whenever possible.

BIM and ERP – separate solutions inseparably connected

One of the biggest misunderstandings is the widespread impression that BIM is merely a modern method of technical planning of the projects. This impression is no doubt aroused by the fact that, from past experience, everyone seeing a three-dimensional building model immediately thinks about the technical office and its task in the classic project procedure. This is wrong, however, and is one of the basic reasons why BIM is often misinterpreted in the construction industry.

It would be correct to say that the BIM building model interprets the task of the classic database in the construction project in a much more intelligent way. In practice this means that all project participants exchange their information via the BIM model. In addition to the purely technical data such as materials (volumes, areas, built-in parts, etc.), this also includes all other data relevant to the project, such as schedules (production, delivery), costs and prices, personal/company-related data (addresses, contact persons, contact details), document management (drawings, files) and of course milestones and approvals. The BIM model serves here as a data storage device and distributor in the project. However, the coordination of the project procedures must take place from a different program.

IDAT-ERP – modern project planning with BIM integration

IDAT-ERP is the new development from the IDAT company that does precisely that. It is a classic industrial ERP program that has been adapted to suit the special tasks and requirements of the precast industry. Functions such as estimate calculation, technical planning, production planning, precast element store, logistics and building site have been added to the standard functions, such as CRM, estimate and document management, resource planning, materials management, scheduling, finance and controlling, or have been specially adapted to the needs of precast concrete element production.

The special feature of IDAT-ERP is its interaction with the BIM building model. The program is able to exchange project or element-related data with the building model. For example, this allows data to be exchanged with the graphic precast element in the BIM model. These data can then be seen or edited by other people in the BIM process.

Here is a practical example of scheduling. The technical office of the precast element manufacturer has edited a Revit model provided by the client so that the individual precast elements now exist in the BIM model. There is an entry called „Delivery date“ in the Revit attributes of each element. The client can now enter the desired delivery date on the graphic objects in the Revit model and return it for confirmation. Following this action, the color of this component changes in the display in Revit, both in the client‘s system and in the precast plant. There, IDAT-ERP now determines the last possible date from production and delivery times defined in advance and checks all relevant parameters such as the availability of materials and personnel, production utilization levels and, if applicable, the availability of storage space and transportation capacities. If external purchase orders, reservations or approvals should be necessary, IDAT-ERP can handle these automatically (provided the workflow for this has been defined in advance) or the responsible person can create a corresponding action job. If a desired delivery date has been confirmed by the precast plant, this information is made available to the client again via the BIM model and the color display of the respective element is changed once again to a new color. This color code provides for a very convenient and clear display. The color code can be extended to cover many other parameters, such as approval status, production status, delivery status, etc.

IDAT Revit Precast – solution for the planning of precast concrete elements

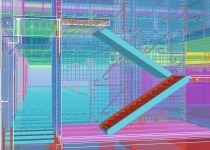

Highly automated and specialized planning solutions have been available for many years in the field of 3D precast concrete element planning. These not only offer functions that have a direct influence on the quality and speed of the planning (e.g. automatic unitization, reinforcement generation and drawing creation), but also support various interfaces such as CAD/CAM for the control of production machines and master computers. IDAT also offers a widely used solution in the form of its CCAD program. In particular companies that use such automation in the plant are forced to rely on these programs.

Until now this has been one of the greatest hurdles for precast element planners, as such a solution was not available from Revit and the entire planning had to be done manually, including the preparation of the element drawings. This was extremely time consuming and was often a bottleneck in the project sequence. Alternatively, there is an option to export the BIM model to other program platforms via interfaces such as IFC. However, this has proven in practice to be complicated and unreliable. It doesn‘t make sense to process the entire project on the Revit platform and then to switch to a different platform in the last stage of the project (the production level).

For this reason, IDAT has developed the Revit Precast program. In the last stage of development, it offers numerous add-ins for Revit Structure with many beneficial functions (see “IDAT Revit Precast - add-ins and functions”, p. 72).

The Bottom Line

Nobody will be able to escape the subject of BIM and Industry 4.0 in the long run, for the reason alone that the conversion of the in-house processes generates a measurable competitive advantage. However, such a conversion needs to be planned in detail beforehand and implemented consistently.

No general recommendation can be given for the necessary software; this depends to a great extent on the individual needs of every single company. The determination of these needs and the planning of the implementation require a certain experience and should not be planned and carried out by the precast plants themselves alone.

IDAT GmbH has been developing and distributing specialized software for precast concrete element manufacturers for 38 years. During this time the company has not only developed into a global player in this industry with installations in over 40 countries worldwide, but has also gained a wealth of experience in the implementation of software solutions at numerous precast plants.

IDAT GmbH offers a comprehensive service that on the one hand contains a software portfolio covering the entire bandwidth in a precast plant and on the other offers consulting on the subject of software conversions to CAD, BIM and ERP solutions.