An integral approach to achieve carbon neutrality

In retrospect, traveling to the moon seems like child’s play in view of the challenge that humanity is facing today: a dramatic reduction in greenhouse gas emissions to achieve climate neutrality. The focus is also on the cement industry. It accounts for around 6 % to 7 % of global carbon dioxide emissions and must therefore make its contribution to climate protection. It is clear to everyone involved: the challenges are huge because conventional mitigation strategies have reached their limits. While technical issues continue to be part of the debate, questions related to costs, protection against carbon leakage and public acceptance of the crucial steps to be taken towards decarbonization are therefore becoming increasingly important.

The cement industry will not be able to achieve this major feat on its own. It will need the support of plant manufacturers and concrete producers, as well as that of designers, architects and the construction industry. In addition, a suitable political framework is needed that will permit the competitive production in Germany of low-carbon cements and concretes while at the same time creating markets for these products.

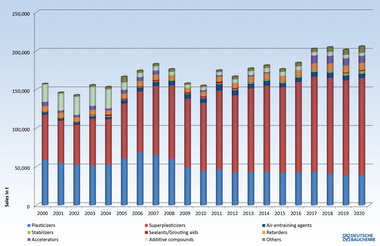

In total, the current domestic carbon dioxide emissions of the cement industry amount to around 20 million tons. This equals around 2 % of the national carbon dioxide emissions. A review shows that the German cement producers have succeeded in achieving a reduction in carbon dioxide emissions since 1990 amounting to between 20 % and 25 % both specifically and in absolute terms. This is an important step forward. In addition to improvements in thermal efficiency, two factors have been decisive for the successes in carbon dioxide reduction achieved to date: increasing the clinker efficiency in cement and the increased use of alternative fuels containing biomass. Much more far-reaching measures will be necessary, however, on the path to carbon neutrality. The partners in the value chain will continue to actively work in four areas:

Portland cement clinker: thermal efficiency, fuel mix, carbon capture and usage or storage (CCUS)

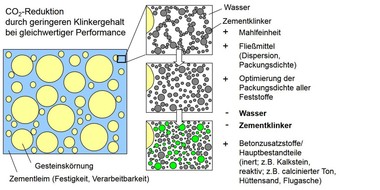

Cement: clinker efficiency

(= clinker-to-cement factor)

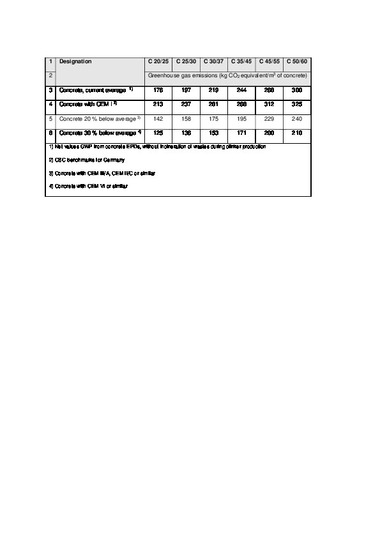

Concrete:efficient and different-iated use of clinker-efficient cements in concretes

Construction:efficient and differentiated use of concrete in structures

Even in view of the somewhat helpful fact that cement-bound construction materials reabsorb carbon dioxide, the essential insight from today’s perspective remains that the goals can probably not be achieved without CCUS (carbon capture and usage or storage).