3D-printed formworks – an alternative to conventional formliners

Mid September 2018 at the first International Conference on Concrete and Digital Fabrication in Zürich, Switzerland, BASF presented its versatile portfolio of innovative solutions under the brand name of Master Builders Solutions. Participants of the conference were able to witness a demonstration of 3D-printed formworks and concrete casted parts, presented by BASF application technicians. The concrete additives and grouts from Master Builders Solutions, optimized for the filling of 3D-printed formworks can already be used on projects today.

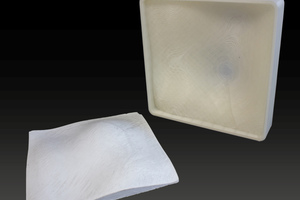

3D-printing is an additive manufacturing process in which workpieces are built up in layers in a computer-controlled process. This way, highly complex shapes can be generated, including formworks for concrete casting. With 3D-printing, formworks are fabricated for walls or facades with integrated patterns which otherwise could not be produced conventionally or only with considerable effort.

Almost everything is possible

In a validation project, Heidelberg-based BASF 3D Printing Solutions together with BASF’s Construction Chemicals division and the Innovation Department NOWlab of Berlin-based BigRep have demonstrated technical feasibility of a series of concrete formworks with the aid of large-format 3D printing.

There are almost no limits to the possible applications of this technology, especially if the formwork is to provide more complex shapes rather than the relatively simple today’s geometries. “Apart from the countless possibilities of templates, 3D-printed formwork can also be used for irregular organic shapes or difficult connecting elements of the type we need in concrete construction,” said Sebastian Dittmar, Head of Applications Technology Germany with Master Builders Solutions. “The facade element is scanned and can then be precisely reproduced by the 3D-printer. This way, it is possible to produce almost any shape you need.”

Further information on innovative concrete additives from Masters Builders Solutions is available at //www.master-builders-solutions.basf.com" target="_blank" >www.master-builders-solutions.basf.com:www.master-builders-solutions.basf.com.