Color control:

The gray of cement

Interview with Dr. Peter Boos, director of Heidelberg

Cement’s central laboratory in Ennigerloh, Germany

Why is cement gray?

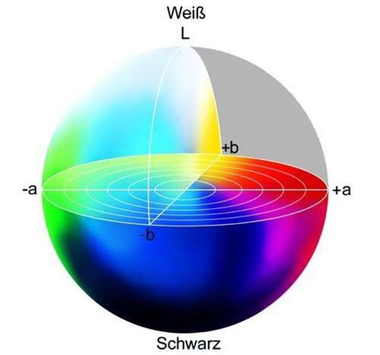

Dr. Peter Boos: This is actually based on the question of why materials have a color. The answer is because they reflect and absorb different degrees of light. If a material completely absorbs light, it appears black; if it reflects all of the light, it appears white. If it only absorbs or reflects certain wavelengthsof light, it appearscolored. The gray of cement sits between the two extremes of white and black.

Where does the gray come from?

Cement essentially consists offour mineral phases: two calcium silicates, a calcium aluminate and a mixed crystal known as calcium aluminate ferrite (C4AF). While the first three appear as pure white minerals, pureC4AF has a brown color because of itsiron content. So theoretically, pure cement would be brown. But that’s just in theory. In effect, cementis a natural product and never exists in mineral phases that are absolutely pure. Thus, C4AF is usually contaminated by magnesium. The quantities are small, but they are nevertheless sufficient enough to partially replace theiron and calciumin C4AF. These low levels of magnesium polarizeand deform the iron’s electron shell. This, in turn, leads to a change in the absorptionof light and the cement appears in its characteristic greenish-gray color.

Then how do the various tones of gray in cement materialize?

In Portland cement, this in large part depends on the iron content in the clinker – the higher it is, the darker the gray becomes because of the magnesium in the cement. For example, in the Paderborn cement plant, we have a rather dark cement because its iron content is high, while at the plant in Geseke, we have a lighter-colored cement with a lower iron content. However, other major components in cement influence the shade of gray. Granulated blast-furnace slag can make the cement brighter.

How does the cement color influence the color of the concrete?

The color of the cement determines the basic shade of the concrete. However, other factors in concrete technology can play a substantial role as well. Examples include concrete composition and surface effects.

What should I do if I’d like to have blue or red concrete?

You can, of course, have colors other than gray by adding pigments – regardless of whether you want blue, red or green concrete. As a basis for colored concrete, it is best to have cement that is as light gray as possible.

Where else does the color value of cement play a role?

In quality surveillance: We regularly check the quality at critical points in the production. For example, we check the chemical composition of the raw meal after it goes through the raw meal grinding plant, or the quality of the cementafter it goes through the mill. Thefreshly-burnt clinker is examined, as are other cement components, such as granulated blast-furnace slag, fly ash, trass, gypsum and anhydrite. Effective multi-analytical measurement techniques such as X-ray fluorescence analysis are used, but light spectroscopy is applied as well. In using these techniques, we investigate the sample’s reflective light and—in connection with the X-ray diffraction—can draw conclusions on the production conditions. For example, we check to see whether the oxygen content in the kiln system is right for theproduction of clinkers. For customers, it is usually important that the color be uniform. Since cementis made from natural raw materials, minor color variations can always occur. However, these variations generally don’t affect the outcome of the concrete’s color.

How was it in the old days?

When the laboratory analysis wasn’t as developed, the laboratory managers looked at the color of the cement clinker and used this as the basis for drawing conclusions about its quality. These were people whowent along thekiln and listened to make sure that the burning process was running smoothly. Their experience played a huge role, of course, but this experience wasn’t objective. Nowadays we have more objective and, above all, more sophisticated measurement techniques to quickly and reliably monitorthe quality.

Whether you choose cement that is dark gray or light gray, is it purely a matter of taste?

Yes, absolutely. The cement’s gray color only depends on the composition of the raw materials. The preferred shade of gray is purely a matter of aesthetic taste. Oddly, this fact is not yet widely known. On construction sites in Poland, I have repeatedly heard that dark cement is good because it apparently creates a very solid, hard concrete. In some regions in Germany, I’ve heard that the concrete needs to be light-colored in order for it to be hard. I have no idea where these misconceptions come from. The color of the cement or concrete is not indicative of its strength.

Which color would you choose for cement or concrete?

As boring as it sounds, I like the gray of concrete a lot. With extreme colors such as red or blue, the risk that you will eventually get fed up with the way it looks is too great. Personally, I feel that gray is neutral and resistant to changes in taste.