PHILIPP expands portfolio by anchor channels

Philipp GmbH, in 2012, has been an innovative, medium-sized companion of the precast concrete industry for 40 years. The close links between the manufacturers of precast concrete component and Philipp is especially noticeable in product development. Among these belonged until now, among others, the development of transport anchor systems or connections loops and channels.

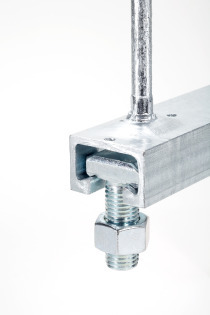

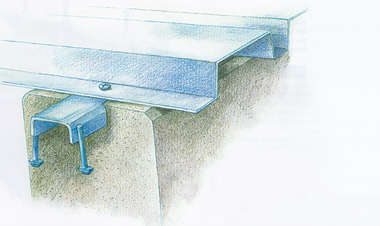

The logical expansion of the product portfolio by anchor channels and trapezoidal sheet channels (incl. the appropriate accessories) is Philipp’s response to the many inquiries in that regard. This has become possible through the sales collaboration with Profilanker GmbH entered into in February 2012 – a highly specialized manufacturer of high-quality and reliable embedded parts, such as all profiles available on the market both cold-rolled and hot-formed. No matter whether hot galvanized or stainless steel, with head bolts or I-anchors, in typical standard lengths or special dimensions, all of a customer’s wishes can be flexibly responded to.

The anchor channel, designed as simple C-profile for universal use that will celebrate its 100 years of existence is known almost everywhere. For in-situ concrete constructions, and especially in precast construction, this opens up comprehensive areas of application (among them, fixing of precast parts, supply and drainage pipes, façades, facework masonry, elevator guide rails. Compared to dowel technology, the anchor channel has undisputed advantages, for example, adjustable anchorage, high loadbearing capacity at small distances from edges without causing damage to structural reinforcement. In this way, the anchor channel has tapped a large market segment with strong ongoing demand.

The design of anchor channels depends first of all on the basis of their approval. The approval granted the anchor channels from Philipp by DIBt is valid until October 2014 for the permissible loads listed in a table. These are based on the test results recorded in the uncracked concrete, taking into consideration a global safety factor. However, the European Technical Approvals (ETA) are also in the works. These approvals are granted on the basis of as CEN Technical Specification (German version DIN CEN/TS 1992-4-3:2009 as preliminary standard), for which the design is based on the safety concept with partial safety factors. Here, considerably more load directions and failure modes are differentiated between, possibly resulting in minor deviations in the products compared to the anchor anchor channels with national approval.