Problems at pan-type mixers solved

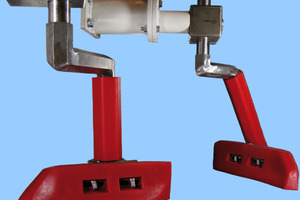

Every person involved in concrete manufacturing knows the countless problems with hardened concrete caused by worn out mixing arm bearings and spring units. Pan mixers of any common manufacturer always show the same weaknesses after a longer period of service life. It starts with worn out arm bearings and leads to a rotor caked with concrete – and it is a challenge for every locksmith to repair such a rotor. Apart from the high costs and the downtimes caused, there is the certainty that these problems will not have happened for the last time. As to put an end to that nuisance, Pucest® protect...