Automation as a model of the future:

The success story of Viguetas Navarras

Viguetas Navarras, a major industry player in Spain, is investing in modern equipment for an automated production of precast concrete elements. Machine technology and software of the Progress Group will thus revamp the construction industry in Southern Europe in a sustainable manner. With the aid of trailblazing technologies, an exciting vision for the construction industry and expansions on an international level, the company proves that modernization is the key to success.

The expansion on the South European market in 2004 and the entry into the French market in 2012 account for the company‘s capability to adapt to international standards. The installation of the pallet circulation system including reinforcement production supplied by the Progress Group, using robotic technology and digitization solutions, revolutionized the Spanish precast concrete industry. The VN-System, the own construction system of Viguetas Navarras, could be introduced successfully in 2021. This system combines all prefabricated elements that are required on the construction site in housing construction: double walls, prestressed beams, ground slabs, balconies and architectural façades (after the acquisition of the precast producer „Dinescon“). Hence, it streamlines construction and increases efficiency.

Automation and digitization as cornerstones of future construction

The decision in favor of automation and digitalization was fundamental for the new development of the system. In this regard, the collaboration with Progress Group as technology supplier proved to be the key to success. Highly automated machines for the production of precast concrete elements and the associated reinforcement followed, as well as innovative software solutions. Along with the complete pallet circulation system and an M-System BlueMesh mesh welding line with bending unit, mesh handling and state-of-the-art welding technology, a Form Master shuttering and deshuttering robot was installed, in order to manufacture the precast elements in a highly automated process. The new circulation system also includes logistics and storage systems, a pallet cleaning device and a modern turning unit.

„The high level of technization and digitization, provided by the Progress Group, was fundamental to our decision to make the greatest investment in our company history so far. The software Ebosyc master control system did not only provide us with useful data but also made an unestimable contribution to improving the three cornerstones of the VN System made by Viguetas Navarras: quality, production and communication,“ states Ivan Ilundáin, production manager of the carousel plant.

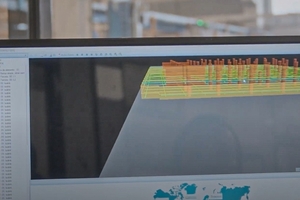

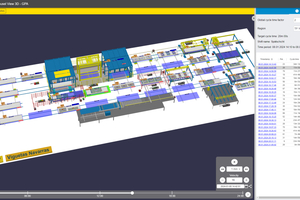

The implementation of the Progess Ebosyc software allows 3D visualization of complex relations in a clear manner as well as monitoring and controlling the entire process in real time. In addition, two camera systems were installed for automated quality control. The fully automated image recording of the precast or semi-precast elements at a certain station allows efficient and reliable quality control. In addition, Ebosyc controls the laser system showing the workers where which embedded parts are to be placed. In this way, it is not only possible to eliminate the yardstick, but also to ensure more precision, control and quality.

Focus on production and quality

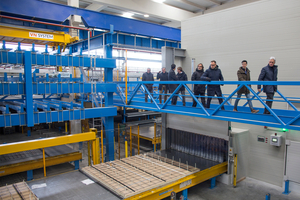

Viguetas Navarras counts on state-of-the-art technology for their two precast concrete plants. The facility in Huarte is specialized in precast floor slabs and prestressed hollow-core slabs. The facility in Barasoain, only 60 km away, is producing on 500 m² architectural façade elements and double walls using the new circulation system of Progress Group. The increased production capacity due to the modern machinery enables a monthly production of 2,500 m² of architectural façade elements and 18,000 m² of double walls.

The automobile industry served as a model for this circulation system, which was installed in a kind of „assembly chain“. This innovative movement concept of the production plant, wherein the element is moved from one station to the next workstation, optimizes the processes and increases the production capacity continuously. Smart Production Screens being installed at every workstation digitally create a 3D depiction of the element to be manufactured currently. At every workstation, the worker interacts with the virtual element on the display, turning and moving it, thus getting all information necessary from the Ebosyc system in real time. The support service of the Progress Group for technical issues provides additional safety and allows the efficient and quick resolution of incidents.

Quality control by digital twin

Four days in advance of the real production of every element, the production process is virtually simulated in the software additionally by digital imaging (digital twin). This phase allows the identification and correction of errors prior to the production, so as to supply precise products of high quality. The integration of the workers into the process by interacting with the digitally created element is crucial for achieving highest quality standards. During this virtual phase, Viguetas Navarras detects and corrects any faults indicated by the software and the machines so that production can run in a precise and flawless way.

Why automation and digitalization?

„Our decision to make an investment in automation and digitalization was taken for several reasons. First of all, we want to increase our operational efficiency by rationalizing tasks and optimizing the input of resources. As a consequence, we are working more flexible and more effective,“ confirms Ivan Ilundain. The reduction of human errors also is of crucial importance and the introduction of automated systems ensures greater accuracy and reliability in comparison to manual processes. Another important factor is the significant reduction in the costs related to working hours and idle times. This not only has a positive effect on the profitability, but also allows the allocation of resources to strategic activities and innovations. An improvement of the quality of the products and services is another decisive advantage.

Vision – helping to shape the future of construction

Viguetas Navarras has a quite ambitious vision of the future. The company makes a commitment to consolidate the industrialized VN System concept to five goals: VN System complete (the construction system with precast concrete elements using industrial prefabrication), training, exchange of knowledge, VN System engineering and environment. Training is regarded as fundamental here. However, the vision even goes beyond training of young skilled workers; Viguetas Navarras would like to share knowledge and technology with the entire sector. The company is planning factory visits of their modern plants, in order to make the advantages and options of industrialization tangible and understandable to building contractors, real estate developers, architects and engineers. For designing buildings efficiently and for inducing a transformation in the housing industry by automation and industrialization, the technology is to be used by the collaboration of internal architects and engineers with external partners.

On the pathway into a sustainable future

In addition to the goals mentioned, Viguetas Navarras also considers environmental protection as a priority. The company uses concretes with an extreme low carbon footprint and subsequently supplies the final customers with exact data of the entire production process. Because not only innovative houses, but also environmentally friendly ones are to be built, with integrating sustainability into every step of the construction works. With the clear focus on innovation, modernization, sustainability and quality, Viguetas Navarras has estabilished itself as a pioneer in the South European construction sector. The cooperation with the Progress Group as one of the leading technology suppliers has laid the foundation for this success and an evolution in the construction industry.

CONTACT

Viguetas Navarras S.L.

Alztutzate 35

31620 Huarte, Navarra/Spain

+34 948 331 111

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159