Decision matrix for best color

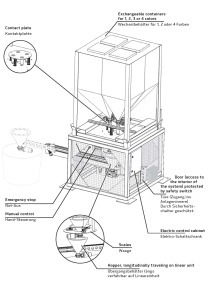

metering solution

During the course of many years we have developed a variety of techniques to dose color pigments into concrete. The goal of this article is to give the reader some assistance in the decision making.

Each producer of concrete products has different needs, different priorities, and goals. For example having a low-cost product strategy versus a quality leadership strategy will result in different decisions concerning the equipment in the concrete plant. The following matrix 1 can be used as a basis for selecting a suitable color dosing system for one’s company strategy.

The first decision you have to make concerns the type of pigment you want to use. There are two main base pigment forms available in the market, powder pigment and granule. Compact pigment will be treated as a form of granule...