A novel approach to additive manufacturing: The vibration-modulated 3D concrete print head

A vibration-modulated printing system developed at IAB Weimar utilizes the thixotropic properties of fresh concrete, eliminating the need for adding a setting accelerator. The gravity-based discharge principle allows for a uniform 3D printing process while expanding the technical options of additive construction. This article discusses the IAB project in detail.

1 Problem definition and possible solution

Driven by innovative technologies and materials, the construction industry is undergoing continuous change. More specifically, 3D printing of concrete will revolutionize the industry because it provides the option of constructing complex buildings and structures directly from printable concrete. However, this process is associated with high demands on the rheological characteristics of concrete. It must remain flowable during conveying and printing and become dimensionally stable (green strength) quickly after discharge without damaging previously deposited layers. Some commercially available material solutions rely on adding a setting accelerator for this purpose, but this type of admixture is difficult to batch and can cause blockage if the printing process is interrupted unintentionally.

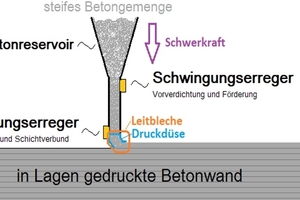

Our approach (Fig. 2) aims to overcome these problems. To achieve this goal, IAB Weimar developed an innovative vibratory concrete print head in our preliminary research that uses concrete recipes with a maximum particle size of 8 mm and sustainable binders. Targeted use of mechanical vibration on the print head makes it possible to liquefy the fresh concrete during the 3D printing process, which triggers its discharge with the aid of gravitational force. This method relies on utilizing the thixotropic properties of the material, which allow for precise modulation of its rheological parameters during the discharge process.

2. System design

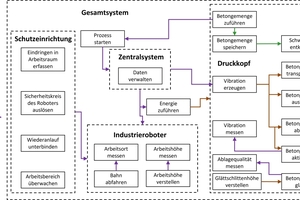

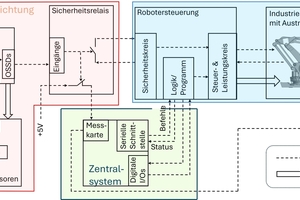

The system design was developed in accordance with VDI 2222. The requirements determined were defined as functions and divided into four modules, namely the central system, the protective system, the industrial robot, and the vibratory print head (Fig. 3). Several proof-of-principle solutions were developed for implementing each of these functions and evaluated regarding their benefits and shortcomings for the purpose of ensuring an efficient, risk-conscious, and objective choice of the most appropriate solution.

3. Mix design

A mix was designed at TU Dresden using the particle size optimization method according to Fuller and Thompson and tested at the IAB Weimar premises applying a proprietary method. Three important requirements needed to be met during mix design:

pronounced thixotropic properties (structural degradation and structural formation)

maximum particle size of at least 8 mm

processing time of at least 20 minutes.

Critical examination of the possible variations in the parameters and thorough discussions gave rise to the decision of not using special cement. Standard cement was initially preferred for the reference mix to ensure reliable results. The paste content of the mixes amounted to approximately 50% (+-5%). Three recipes were developed based on these specifications. For all designs, the grading curves of the materials were first determined, and particle sizes were optimized at a later stage. The final recipe comprises aggregate, water, superplasticizer, and binder compound (limestone powder, calcined clay, anhydrite, and cement, where the cement content accounts for up to 60% of the compound).

4. Mix testing

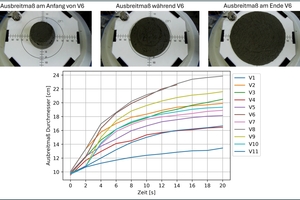

A method was developed at the IAB for testing the mixes. Mixes are first tested on the Hägermann table to determine their consistency as a function of the amount of water and superplasticizer. If the consistency is appropriate, long-term tests are conducted to determine the processing time window of the mix. The influence of vibration on the mix can then be investigated using the electrodynamic, software-controlled shaker according to a statistical test schedule (Fig. 4). The second aim of testing was to determine the behavior of the flowing material after turning off vibration. At all test points, the mix came to a halt immediately after vibration was switched off.

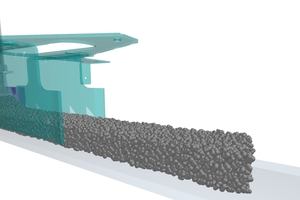

5 Simulation

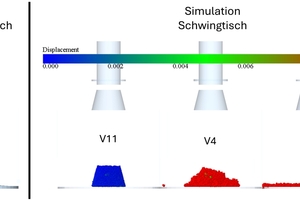

Besides the tests described in Section 4, rheological measurements were conducted using the Viskomat NT, as well as uniaxial compression tests and slip tests on inclined planes. The resulting values were used for the extended characterization of fresh concrete properties. Experimental tests were then simulated numerically applying the discrete-element method (DEM) (Fig. 5). The parameters of the material model were calibrated iteratively until a high degree of consistency between experimentally observed and simulated material behavior was achieved.

The simulation model developed at the IAB is based on the Bingham approach and was extended to include the mapping of thixotropic effects as part of the project. The 3D printing process was simulated successfully using this extended model (Fig. 6). The simulation was used to design and compare different design variants during the process. More specifically, the nozzle discharge direction (vertical discharge using a straight nozzle vs. horizontal discharge using a deflection nozzle), different vibration regimes (internal vs. external vibrators, direction of vibration along or transverse to the discharge direction), and material feed variants were investigated.

6 Design and installation of the demonstrator

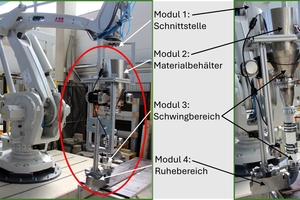

The detailed design and mechanical installation of the demonstrator was based on the experience gained from laboratory discharge tests. The print head consists of four submodules (Fig. 7), namely the robot/print head adapter (interface), the material container (vibrating), the vibration zone (structural degradation), and the no-vibration zone (structural formation).

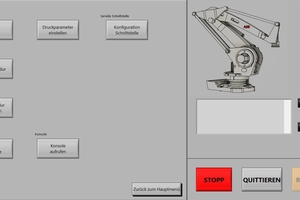

At the same time, the industrial robot and the central system were programmed at the IAB (Fig. 8).

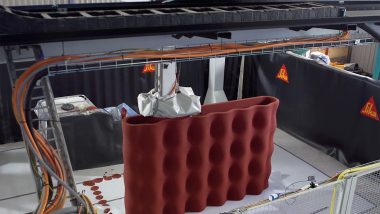

7. Tests on the demonstrator

The first run-in tests quickly showed that the two vibrators mounted on the container were sufficient to liquefy the material up to the print head and to discharge it with the aid of gravity (Fig. 9). The elastically designed connecting tube between the container and the print head ensured effective transmission of vibration. The vibration-decoupled trowel carriage worked relatively well on the demonstrator, but there is still room for improvement before it can be used on a real construction site.

8. Investigation of physical characteristics

Seven-day strength values were used to determine comparable strengths in a timely manner. Because the current print head only produced 70 mm wide layers, the standard 150 mm edge length could not be examined in the cube tests. This is why cubes with an edge length of about 50 mm were cut, and their strength values were determined based on the DIN EN 12390-3 standard. Furthermore, prisms with bonded layers measuring approximately 160 × 40 × 40 mm were cut out of specimens for flexural tensile tests. Average bulk densities of about 2.1 g/cm³, compressive strengths of about 33 N/mm², and flexural tensile strengths between 6 and 8 N/mm² were measured for the prisms.

Sections (Fig. 10) show that the individual layers are firmly bonded to each other – there is no discernible layer separation. Only a few air voids are introduced owing to the gravity-based discharge of the mix.

9 Conclusion

The results achieved meet the objectives of the project. Basic principles of the innovative 3D concrete printing process were determined and implemented for testing with a laboratory test rig designed for this purpose and, at a more advanced stage of the project, on a robot-assisted demonstrator. The functionality of the process has been proven and a European patent application has been filed. The process was already presented at Innovationstag Mittelstand des BMWE 2024, at Bauma 2025, and at the 2025 IAB-Tage “BETON” and has sparked great interest. Major construction material manufacturers, including Sika AG and Sievert SE, supported the development by making their mixes available free of charge for testing and use with the new print head. Concrete was also discharged successfully in these cases.

A presentation of the IAB project is also available at https://www.iab-weimar.de/vibrationsmodulierter-3d-betondruckkopf/(in German).

CONTACT

IAB – Institut für Angewandte Bauforschung Weimar gGmbH

Über der Nonnenwiese 1

99428 Weimar/Germany

+49 3643 8684-0