Resource conservation for foundation slabs with optimized void formers

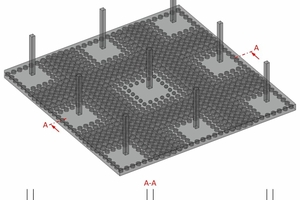

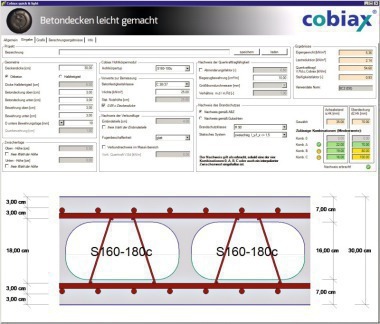

In an increasing number of biaxial reinforced concrete slabs, void formers are arranged to displace concrete in those areas, where it is not needed to ensure bearing capacity and serviceability limit state. Within the scope of the BMWK in the Technology Transfer Program for Light weight Construction (TTP LB), the joint research project “air-Kon-Matrizen”, for further

development of this technology, is currently under way. The object of the project is, first, the development of inflatable void formers and, second, development of other variable sizes and shapes of the void formers. A range of various void former types is being developed. They are intended for application in foundation slabs.

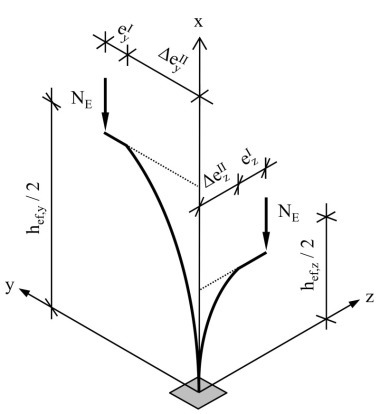

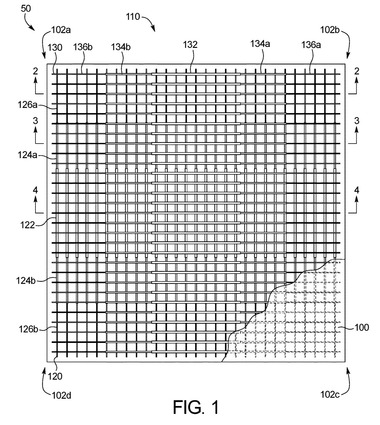

The void formers are arranged according to the stresss. For this purpose, research focuses initially on optimizing different geometries of void formers for various combinations of bending

moments and shear forces, to maximize the possible volume reduction of concrete. Optimization is performed by means of genetic programming and results in a catalogue of void former shapes. From this catalogue, the void former that withstands the existing combi-nation of bending moments and shear forces can be selected for each part of the slab, therfore maximizing the possible displacement of concrete in the slab. The desired high-bearing capacity of reinforced

concrete slabs with such innovative void formers was demonstrated in real-scale component tests and in non-linear 3D-FEM simulations with comprehensive parameter variations. For this purpose, otherwise similar test specimens with void formers of various geometries and volume displacements were tested.