New Alpha 3-3500 compression testing machine

According to the leading motto „acting instead of reacting – developing instead of replicating“, Form+Test Prüfsysteme based in Riedlingen has extended the Alpha 3 testing machine series. Now, they are also manufacturing a compact machine with a maximum test load of 3,500 kN. This allows tests on cube specimens with edge lengths of 150 x 150 x 150 mm up to 155 MPa (N/mm²).

This model has been especially developed for customers, for whom the difference from 3,000 kN to 4,000 kN is too great in terms of the higher costs involved as well as because of the extended floor space requirements. In comparison to separately arranged components, the compact design has the advantages of a considerably faster and thus more cost-effective installation and resource-conserving maintenance with lower maintenance costs as a consequence.

The testing frame is manufactured in the own production plant in Riedlingen as a special four-column design. It features an extremely high degree of torsional stiffness and the least possible expansion. The pendulum axle (so-called calotte) of the expansion cylinder is made of special steel as a strengthened version in an especially optimized production process. Load measurement is carried out by means of precision oil pressure transducers with throttle for precise and repeatable measured values.

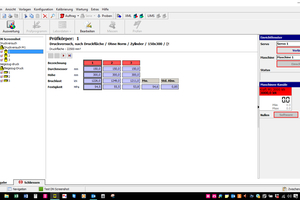

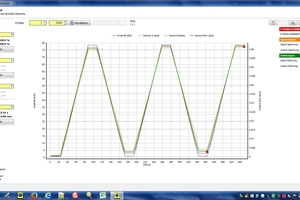

Exact load increases (freely selectable) are realized by means of a very fast reacting special servo valve in combination with the further developed DigiMaxx C 40 digital controller operating in a closed loop system. Operation is carried out by an integrated touch display in stand-alone mode or via PC operation. Remote maintenance programs are a given. Measured value recording and data storage as well as evaluation and issuing of test reports with the aid of especially developed testing software programs (ProteusMT) and data interfaces to be also used for exporting of measured data into external laboratory programs come as standard (among others, LaStrada – Beton+Computer – COBET, and many more).

It goes without saying that this testing machine can also be extended for the determination of the modulus of elasticity according to EN 12390-13. Piston displacement and/or deformation controls are possible as additional applications.

CONTACT

Form+Test Seidner & Co. GmbH

Zwiefalter Str. 20

88499 Riedlingen/Germany

+49 7371/9302-35