Josef Lehner invests in state-of-the art double-wall production

As a 2nd generation family business, the Austrian construction company Josef Lehner stands for sustainability and foresight. As part of the expansion of its capacities for larger construction projects, the company has now invested in a modern, partially automated double wall production facility at its headquarters in Amstetten.

The long-established company Josef Lehner GmbH has been one of the pioneers of precast concrete production in Austria since the late 1960s. „Today, we are significantly active in turnkey commercial and industrial construction, as well as in residential construction and infrastructure projects,“ explains Managing Director and owner BM DI Günther Lehner. „We not only work sustainably on our construction sites in terms of conserving resources. Healthy, cross-generational growth was and is important to us as a family business. We have always combined tradition with innovation and investment in new technologies.”

Double walls essential for own construction projects

Against this background, Josef Lehner has developed into one of Austria‘s largest precast concrete specialists. High quality standards are the benchmark, whereby special accents are created with various surface textures such as exposed aggregate concrete, sandblasted effect or color additives. In addition to prefabricated floor slabs and structural reinforced concrete components, double walls are essential in the company‘s own construction projects in order to optimize time and costs.

Since the end of the 1980s, double walls have been produced in Amstetten, predominantly stationary on several folding pallets as a single workstation solution, combined with a high proportion of manual work. „In order to meet the increasing capacity requirements and respond to the growing shortage of skilled workers, the focus was on a significant increase in the degree of automation - circulation-based instead of linear and stationary,“ explains Ing. Michael Veits, Head of Production at Josef Lehner. In spring 2022, the decision was made to implement this concept with system supplier Vollert as a strategic technology partner.

Expansion of existing systems

‚We act in awareness of our three core values: vision - handshake - realization‘, is how the long-established company describes its core philosophy. „This was immediately apparent from the very first contact,“ says Markus Schenk, responsible Senior Sales Manager at the plant specialist Vollert. During the further preliminary planning phase, an optimum system concept was developed in an intensive exchange under the leadership of the planning office Martin Dobler Projektmanagement, which is also future-proof for further expansion.

„The challenge was that we are building in Amstetten in an established plant and building stock. The extremely compact footprint of the new plant line of around 1,200 square meters is also special,“ explains Markus Schenk. The previous stationary production line was completely dismantled, new foundations for the plant technology were concreted and further preparatory construction work was carried out. Existing machine technology such as lasers or a concrete dosing bucket were also taken into account and integrated into the plant concept. „From day one, we were in an intensive partnership-based dialog, which was very important for the subsequent successful start of production,“ Markus Schenk continues. „It quickly became clear that we didn‘t need an off-the-shelf concept. We needed an experienced system partner who could respond to this individual situation, and we found one in Vollert,“ explains BM DI Günter Lehner.

Efficient and economical - the system technology

„As much automation as necessary, combined with state-of-the-art machine technology and permanent quality checks - that‘s a good way of summarizing the plant layout,“ explains Antonios Fischer, Project Manager at Vollert. „Particular attention was paid to the storage and retrieval routes for the first and second shells of the double walls. The production-side sequences must be monitored by the control system so that the line cycle is not blocked.

The new machine technology has been optimally adapted to the existing space conditions and processes have been designed so that production can be flexible depending on the current construction project. The fully insulated Vario Cure curing chamber forms the central core. The shelves are approached for the curing process via a stationary Vario Store storage and retrieval system. Up to 12 freshly concreted wall elements or empty pallets can be stored and retrieved in the curing chamber. „For further capacity expansion, foundations have also been prepared for a second curing chamber, which can also be accessed via the existing storage and retrieval unit,“ reports Antonios Fischer from Vollert.

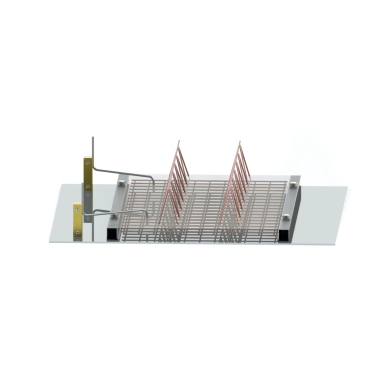

In double-wall production, a stationary Vario Turn pallet turning device ensures a simple, semi-automatic turning process and particularly ergonomic workflows. The clamping arms for pre-locking the first shell are no longer inserted manually before the turning process, which is time-consuming, but remain directly on the turning device so that the first shell of the double wall is held securely on the turning beam during the lifting and turning movement. A high-frequency Smart Compact vibrating station ensures efficient compaction of the fresh concrete of the first shell before curing or of the married double wall after the turning process.

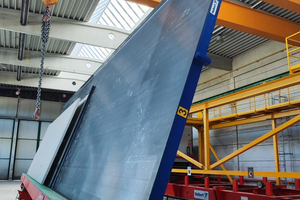

Efficient processes also determine the loading technology. A Vario Tilt high-performance tilting station lifts the double walls vertically. This takes place up to a maximum tilting angle of 80°. A hydraulically movable support beam moves against the wall or the fixed edge formwork, preventing the concrete element from slipping during the tilting process. When the tipping station is set up, a second empty pallet can pass the working position without any loss of time. Loading then takes place directly onto the transport racks provided.

All machines and processes are controlled via the Vollert Control Center (VCC) as a server-client installation. The production queue for upcoming orders is prepared, pallet assignments are created automatically or pre-assigned pallets are transferred from the CAD system. Furthermore, all machines and the projection lasers are controlled, data is automatically tracked and processed, curing times are managed, retrieval sequences are created and a large number of statistics are made available. Remote access also provides the option of quick and direct access to the system control and the production control system for service or support cases in order to make any necessary adjustments.

Continuing the success story

„We have been successfully producing double walls for our construction sites in Austria here in Amstetten since January 2024,“ says Ing. Michael Veits, describing the current situation. „The introduction of the new technology is undoubtedly another major milestone in Josef Lehner‘s success story. We can now offer our customers even more individual solutions and respond flexibly to inquiries and special requests at any time.“

The vision of sustainability is also being pursued further. „Not only does a 400 kWp photovoltaic system supply the new double wall production with electricity, a modern water treatment plant ensures that resources are conserved and the company‘s own rail connection ensures climate-friendly transportation of the concrete elements to the construction sites. With the new plant technology, we are further reducing our CO2 footprint through optimized processes and less use of resources,“ summarizes BM DI Günther Lehner.

CONTACT

Vollert Anlagenbau GmbH

Stadtseestr. 12

74189 Weinsberg/Germany

+49 7134 52-0