Vibration and control technology

for efficient precast garage production

The company Emil Steidle GmbH & Co, manufacturer of precast garages, commissioned the planning and implementation of a garage formwork system with fine-tuned vibration technology and efficient control engineering. The project was successfully carried out in close collaboration with Wacker Neuson concrete solutions.

It’s not always the masonry-built variety: many homeowners decide on a precast concrete garage. The advantages of these garages are rapid erection, flexible sizes and fitting options, and a comparatively favorable price. For manufacturers of precast garages, it is therefore especially important to organize their production processes as cost-efficiently as possible. A sophisticated formwork system, combined with a precisely matched vibration and control system, can provide an important contribution towards this objective. This is illustrated by a concept developed by Rothmund Maschinenbau GmbH, in close collaboration with Wacker Neuson concrete solutions.

Focused expertise

Rothmund Maschinenbau GmbH, based in Bad Buchau in the German state of Baden-Württemberg, is one of the leading suppliers of systems for the production of precast concrete garages. It specializes in individually designed and constructed formwork systems, vibration tables, and tilting tables. The modernization, repair, and maintenance of formwork and accessories are also part of the company’s portfolio.

Rothmund closely collaborates with Wacker Neuson concrete solutions, based in Munich, in the field of vibration technology, control systems, and automation engineering. Wacker Neuson, specialist for industrial concrete processing, supports Rothmund Maschinenbau GmbH with consultation and planning for all aspects of concrete, and delivers vibration equipment and customized control systems for formwork systems. The deciding criterion for their successful collaboration is: close collaboration beginning in the early planning stage of a project, including the end customer.

Plant conception tailored

to the customer’s requirements

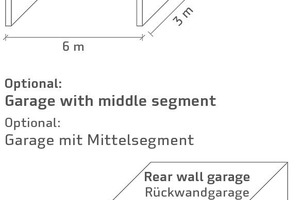

This project called for planning and implementation of a formwork system for a garage with finely tuned vibration technology and efficient control, for Emil Steidle GmbH & Co. KG, a manufacturer of precast garages based in Sigmaringen, Germany. The objective was to improve the existing production of precast garage elements and to increase efficiency and process reliability. To ensure success, the teams of experts from Rothmund and Wacker Neuson concrete solutions sat down with the customer at an early stage.

“The casting of precast garages presents a number of challenges, owing to the special procedure that needs to be followed,” explains Technical Director Wilhelm Rothmund, who together with his brother Paul Rothmund is in charge of Maschinenbau GmbH. “Our customer demands high quality. The blank castings produced with the new form were required to meet strictest quality requirements.”

The formwork system was built exactly to the described specifications to meet the day-to-day requirements of the manufacturer of precast garages. It is fitted with a converter, by which the various forms can be activated as required. The system as equipped with 19 type AR 54/6/250 Wacker Neuson external vibrators, able to withstand very high temperatures – an important factor in meeting the customer’s demand for external vibrators with a long service life. These very robust, high-performance vibrators are designed for intensive utilization and offer high operational safety – even if things literally heat up. Equipped with individual temperature-resistant cables matching the geometry of the form, and an FUE-M 71 A Wacker Neuson frequency converter of special design with motor protection switches, the risks of thermal overloading are virtually eliminated. For production of the garage floors, Emil Steidle GmbH & Co. KG was additionally supplied with a compact tilting table fitted with six AR 54/6/250 Wacker Neuson external vibrators that can also be operated with the FUE-M 71 frequency converter from Wacker Neuson. “The customer is very satisfied with the plant and is looking forward to absolutely reliable operation,” says Wilhelm Rothmund.

The system in practice

“Casting with the hydraulically braced formwork system takes places in several stages,” explains Dennis Hoos,“ responsible Project Manager in the Technical Sales Department of Wacker Neuson concrete solutions. ”The high reinforcement percentage can easily cause quality problems during casting. For that reason, continuous compaction is especially important. We achieve this now by increasing the original 10 to 12 vibrators to 19. Evenly positioned, they now ensure better distribution of vibration input.”

The walls of the garages are manufactured first, by successively casting and subsequently vibrating a layer of 1.0-m concrete into the form. The roof element is cast and compacted last. The side walls are approx. 2.50 m high. A lamp indicates errors that occur during the production process, and the motor circuit breakers are activated. The control panel is moreover provided with an emergency button that immediately shuts down the plant if needed.

Made-to-measure intuitive control

Manufacturers of precast garages must often produce large quantities of reliable, good quality. Here, the combination of formwork, vibration equipment, and control engineering have a crucial influence on the overall manufacturing process and the final result.

“To enable us to offer our customers an absolutely user-friendly, precisely coordinated and complete package, we also requested Wacker Neuson concrete solutions to develop a control concept for these garage forms,” explained the Technical Director Wilhelm Rothmund. “We envisioned a well-organized control panel for the users to enable them to control all functions from one control panel, contributing in this way to greater efficiency and process reliability.”

Dennis Hoos adds: “Thanks to very close coordination and specific demand analysis, we were able to adjust the control functions exactly to the requirements of the customer. The control panel was designed such that all control processes were imaged 1:1, enabling the operator to work with the panel precisely in parallel with the actual production process.”

The process flow in detail

In this way, a made-to-measure control module was created – from selection of the functions to the arrangement of the control elements – which allows the operator to select the required shuttering sections, frequencies, and vibrators, and to run the vibration process optimally according to the production schedule. The system offers the following selection options:

1. Preselection of the downstream forms via a rotary selection switch at the frequency converter

2. Selection of the desired vibration frequency

3. Preselection of the vibration level in the respective shuttering section (wall bottom, wall top, and floor)

4. Activation of the preselected external vibrators

5. Preselection of all 19 attached external vibrators for re-compaction of the complete garage

6. Activation of all connected external vibrators

Multiple advantages for the garage manufacturer

Time is an important factor in precast production – which likewise applies to the production of precast garages. Elimination of manual labor and walking distances gives manufacturers an important time advantage. Effective control engineering supports this efficient working procedure and increases production output at constant high quality.

“With this complete package, we can offer our customers genuine added value,” emphasizes Paul Rothmund. “Experience in practice and the positive feedback from Emil Steidle GmbH & Co. KG show that production runs smoothly and that the operators of the plant have no problems with the control system. The precise, logical imaging of the production process and the self-explanatory operator module reduce time and error rate.