Tilting table production with crane-couplable concrete distributor for the Danish company Give Elementfabrik A/S

Danish Give Elementfabrik A/S is a leading supplier of concrete and lightweight concrete elements for agriculture and industrial construction. Founded in 1964, the company has a total production capacity of more than 18,000 m² per week at its three production sites in Give, Nørre Snede and Gedsted.

Give Elementfabrik A/S is a leading supplier of concrete and lightweight concrete elements for agriculture and industrial construction. Founded in 1964 by Jens Hessellund Eskildsen and today managed by his sons Jens Henrik and Finn, the company has a total production capacity of more than 18,000 m² per week at its three production sites in Give (where the company’s headquarters is also located), Nørre Snede and Gedsted.

In close dialogue with customers, new products are constantly being developed and launched on the market. In the past, these were mainly products for agriculture, but Give Elementfabrik has increasingly developed into one of the leading suppliers of high-quality façade elements.

Therefore, new investments have been made again and again in recent years. On the one hand, due to the constantly changing demand for high-quality façade elements, but also with the aim of reducing CO2 emissions and making improvements with regard to sustainable building.

Among other things, a modern administration building and a new production hall were built. In addition, investments were made in a central mixing plant with a recycling system and bucket conveyors for concrete transport. Much of this was done in-house, and even the planning was done by the company‘s own highly qualified employees.

Thanks to the investment measures described above, Give Elementfabrik is now able to produce sandwich and solid walls with a maximum length of 15 m and a width of 4 m in any thickness and up to 30 t total weight, to load them and to process them on the construction site.

Production of high-quality façade elements on tilting tables

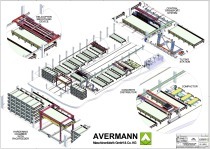

After Avermann had already supplied tilting tables to Give Elementfabrik A/S several times in recent years (including three 75 m long tilting tables for the manufacture of precast elements for agriculture in the mid-2000s) and the company is extremely satisfied with the previous deliveries, the equipment for the new production hall was also requested from the German plant manufacturer again.

True to Give‘s philosophy of producing precast concrete parts without occupancy losses on ultra-long tilting tables, two pieces of tilting tables à 75 m in length, but with a width of 4.0 m, with a load capacity of 7.5 kN/m² were again delivered in 2020. Including the high-frequency vibration technology for compacting the concrete elements.

All side forms as well as the hydraulic synchronisation control by means of a gearwheel flow divider were provided by the customer.

The tables are mainly used to produce sandwich elements with complex façade designs (exposed aggregate concrete, clinker, structural façades, etc.) but also solid elements for both housing and industrial construction.

Concreting device for feeding the tilting tables

At the beginning of 2021, further measures were taken to make the tilting table production even more effective. An additional hall crane was needed and a concrete distributor for feeding the tilting tables was to be purchased. Combined with the requirement to enable concreting on the tilting tables in all areas of the hall continuously and without permanent interruptions due to time-consuming fetching of the concrete from the mixing plant.

A bucket conveyor system for transporting concrete into the production hall was already available, so that the solution of a 20 t special crane with a crane-couplable concrete distributor, which was often supplied by Avermann, was used. See also the photo on the cover page.

The two-girder overhead crane with 20 t lifting capacity was supplied in a special design with a lowered trolley track. However, to be able to use the crane for normal tasks such as lifting the manufactured precast concrete parts, the concrete distributor is simply hooked onto the crane and guided via a corresponding adapter on the trolley frame.

Connecting and disconnecting the machine, including automatic power supply, takes just two minutes.

The concrete is supplied via the bucket conveyor. After the operator has requested concrete, the correct mixture is produced in the mixing plant via a corresponding control system and transported to the crane with concrete distributor by means of a bucket conveyor. The concrete can now time saving be transferred at any point in the hall.

The capacity of the concrete distributor is 2.5 m³. Via a separate hydraulic lifting unit and in connection with a turning unit, the concrete is precisely discharged onto the tilting tables. All functions are radio-controlled.

Summary and preview

The demand for high quality precast concrete elements in various designs is estimated to be very high in the coming years.

Give Elementfabrik A/S is facing up to these current challenges. Future construction will be increasingly shaped by the changing demand for high-quality precast concrete elements, but also by the requirements regarding the reduction of CO2 emissions and sustainable construction.

For more than 75 years, Avermann has been supplying its customers with equipment and machines to manufacture precast concrete elements. Even special challenges are no obstacle; creativity and tailor-made solutions are required here.

CONTACT

Give Elementfabrik A/S

Hjortsvangen 19

7323 Give/Denmark

+45 7670 1540

Avermann Betonfertigteiltechnik GmbH & Co. KG

Lengericher Landstr. 35

49078 Osnabrück/Germany

+49 5405 505-0