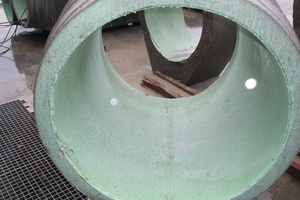

Surface treatment for concrete pipes

When concrete comes into contact with especially aggressive liquids or types of air as occurs, for example, in wastewater, its otherwise high durability is considerably diminished. The prototypes for its application are ready and documentation on an estimated global business potential of 65 billion euros, alone for wastewater pipes, available. Boerthy-Glass is a unique method for finishing all types of wastewater pipes and is especially suitable for protecting concrete surfaces in general, as well as concrete roof tiles, slotted floors in stables, and gas tanks.