Superior concrete surface quality at Prefabbricati Zanon

Prefabbricati Zanon is a long-established business that has been operating for more than 50 years. The Italian company manufactures precast concrete components for multi-story buildings, including floor slabs of any load capacity and a high surface quality of the elements.

Prefabbricati Zanon is a long-established business that has been operating for more than 50 years. The factory is located on a site that extends over an area of more than 100,000 m². The company was founded by Primo Zanon and began as a small prefabrication business. His sons, Alessandro and Giovanni, took it forward enthusiastically and with dedication, passing on the company’s values and the passion for what it does to a new generation.

Prefabbricati Zanon operates two concrete manufacturing plants of high output capacity. The quality and strength of the concrete are constantly monitored and undergo thorough checks in order to ensure the quality of every single component. Computer-controlled manufacturing processes are used for grading, mixing, and concrete pouring to ensure an excellent final appearance.

Prefabbricati Zanon transports and erects the prefabricated components using its own large fleet of vehicles and its own highly skilled personnel. The technical office is the nerve center of the company where expert professionals oversee all stages of design, production, erection, and finishing. The entire process is carefully planned to ensure that the company meets its true objective: complete customer satisfaction.

The proven commitment and professionalism of Prefabbricati Zanon, developed over many years of operation, have enabled the producer to meet the ISO 9001:2000 quality standard for:

The design and manufacture of precast concrete structural components

The transport and erection of precast concrete structural components and

CE marking of the products.

Prefabbricati Zanon also holds a Certification of Qualification for the Execution of Public Works (SOA) in category OS13 and is certified to the OHSAS management system for health and safety at work.

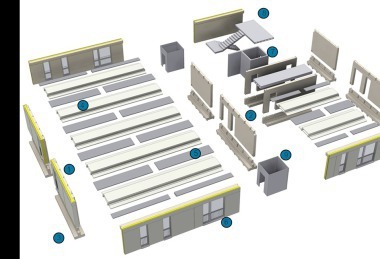

Different prefabricated roof elements

Prefabbricati Zanon began manufacturing the “Z-Shed” roof in 1983. North-facing rooflights enable natural daylight to be utilized and uniformly distributed, creating well-lit spaces that have a spectacular appearance.

The special orientation and slope of the south-facing pitch of these components make them suitable for the installation of photovoltaic panels, thus guaranteeing excellent energy performance. “Z-Shed” beams are manufactured to different depths (130/150/160/170 cm) for different spans. The maximum span is 30 m and the components have a fire rating of 180 minutes (R 180).

In 2003, the need to address new market demands led to the development of the new “Euroshed” north light roof, in which the south-facing pitch is supported on a central box beam. The south-facing pitch of the “Euroshed” roof consists of concrete components supported on structural elements, giving a window opening of approximately 1 m in height.

The south-facing pitch of the “Eurozenitale” roof consists of two inclined concrete elements alternating with pitches in fiber-reinforced concrete at approximately 5 m centers. Initially, only curved south-facing pitches were produced; flat pitches were introduced later so that photovoltaic panels could be installed. The transversal beam can span up to 32 m and has a fire rating of 180 minutes as well.

Since its introduction in 1972, the “Europiana” flat roof has been marketed as a sound-absorbing flat roof, thanks to its incorporation of intermediate panels of 8 cm thick expanded clay. The “Europiana” flat roof consists of I-beams of various depths positioned at variable centers depending on the required imposed loading and spans, with expanded clay panels or 20 cm thick polystyrene foam sandwich panels spanning transversally between the beams. The “Europiana” beam (R 180) is manufactured in four different depths (75/83/105/113 cm) and web thicknesses ranging from 8 to 25 cm.

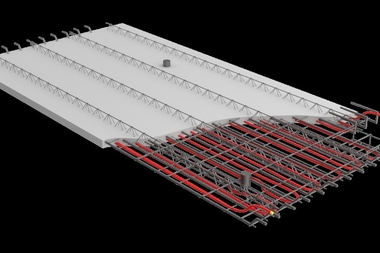

Production of prestressed concrete

Prefabbricati Zanon manufactures components for multi-story buildings, including floor slabs of any load capacity. The main type of floor consists of hollow precast floor planks. The slab consists of prestressed concrete planks in a standard width of 250 cm. The slab depth is determined by the required loads. The concrete planks are self-supporting, which eliminates the need for temporary support during erection. This type of slab eliminates the need for a structural screed and is thus the perfect solution for the installation of a floating floor.

The company uses highly automated adjustable formwork to cast variable depths and widths of large-span I, inverted T, and L-section transversal beams of high loading capacity for use as edge beams, as supports for overhead cranes, and for absorbing the loads imposed by floor slabs.

MCT Italy supplied the flying bucket for the old plant and the complete batching plant including concrete distribution system with flying bucket for the new plant.

Precast experts enthusiastic about surface quality

The participants of „Technical Mission to Italy“ included precast experts from Argentina, Brazil, Canada, Finland, France, Germany, Italy, Portugal, Saudi Arabia, Spain, Switzerland, and the United States, among them a large number of business owners/managing directors and plant managers. All of them were truly enthusiastic about the superior surface quality of the precast panels, whose visual appeal and touch equals that of much more expensive elements made from natural stone. Surfaces of panels can be treated to give polished, brushed or hammered finishes that can be either smooth or polished similar to marble, rough like unpolished stone, grooved in different patterns, or finished to custom designs. In order for the panels to be mechanically milled and hammered, they are manufactured using a mixture of structural concrete and marble chips in different colors.

The use of high-quality concrete means that the panels are resistant to wear, temperature variations, and dirt, and also minimizes any problems caused by deformation or surface cracking over time.

CEO Maurizio Frasani, of the trip organizer, CSG Engineering, also greatly appreciated the outstanding cooperation with Prefabbricati Zanon: “Giovanni and I have known each other for so many years, and it’s always fun to work so closely with such a renowned precast producer. I can’t really imagine a better win-win situation.”