Start-up delivered first production plant to Thailand

South East Asia has been regarded as a continuously growing economic area for a number of years. By now, Thailand is known as one of the so-called small Tiger States. From 2015, after some difficult years, the construction sector attracted attention high with a growth rate of 12 %. This positive trend continued into the years 2016 and 2017. For the coming years, an annual requirement of 50,000 to 60,000 apartments is forecast.

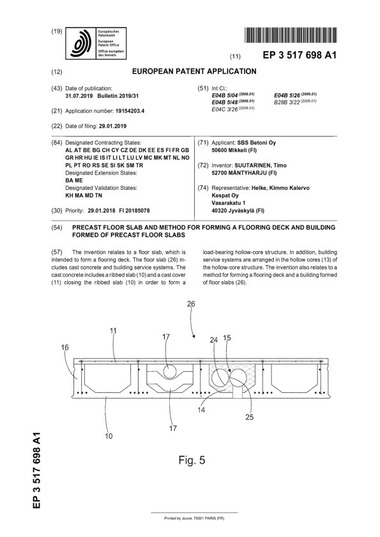

The company MAX-truder GmbH, a dynamic German start-up, which evolved from the insolvent company Weiler, with its experienced workforce, recently delivered its first plant for manufacture of precast prestressed hollowcore floor planks to Thailand.

The new MAX-truder compact was implemented in an existing slideformer. What makes this so special is that the MAX-truder compact manufactures hollowcore concrete planks in thicknesses of 8, 10, and 12 cm, which are typical for the region. These planks are used as permanent formwork.

13 % material savings achieve higher output

Due to a hollowcore ratio of nearly 30 %, the hollow plank of 8-cm thickness is 13 % lighter than the popular solid floor plank of 6-cm thickness and has, in comparison, markedly better structural properties: e.g., the surface resistance is more than twice as high.

Apart from the savings in weight and, accordingly, concrete, the reduced cement requirements add to the savings. The new MAX-truder is one of the so-called vibration extruders and needs only 300 to 320 kg cement per m³ of concrete. This, according to the manufacturer, reduces cement consumption by 15 % compared to the typical extruders and slipformers on the market.

The plant was delivered to the customer and put into operation already in September 2017. Production takes place on a total of 8 steel lanes of approx. 140 m length, and up to 1,000 m² are manufactured daily.

Hollowcore floor planks and wall panels

The high installed compaction energy level enables processing of very dry concrete; the water-cement ratio is as low as 0.28 to 0.30. The tensioning wire can be released after only a few hours; the lane is ready for new occupation, thus doubling the capacity of the new MAX-truder compact.

Apart from the floor planks, the new MAX-truder compact is also suitable for production of hollowcore wall panels of lightweight concrete. The MAX-truder is impressive with hollowcore flooring and panels of maximum strength, material savings (especially in cement), maximum performance, and optimal efficiency – as a system for floor planks and wall panels.