Special façade for research building of RWTH Aachen

A new, state-of-the-art research facility for the RWTH Aachen University of Excellence has been built on Aachen’s Melaten campus. The Center for Biohybrid Medical Systems, CBMS for short, also impresses with an innovative precast element façade.

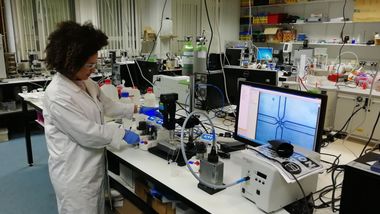

On a usable floor space of around 3,800 m², three stories altogether have been created for system laboratories which allow the flexible configuration of interacting units of mobile design. The central objective of the researchers is to provide better medical care for people suffering from chronic diseases. In the laboratories, research will be conducted on so-called biohybrid systems which are used, for example, for the production of tiny implants or organ support systems. Prototypes are to be developed and tested in a clinical environment.

The new building offers excellent facilities for the task at hand: in “systems laboratory areas” specifically designed for the purpose, components can be assembled to form initial production units. The aim is to demonstrate and ensure the feasibility of the complex medical systems as early as in their creation stage. Needless to say that such an innovative building calls for an innovative façade.

X chromosome design

Precast concrete element façades are perfectly comparable to an iceberg. The visible surface does not immediately reveal that a much larger part is hidden underneath: design expertise, integrated technology and hidden details which not only ensure smooth processing on the construction site but also make a significant contribution towards the exclusive quality image of the entire façade system.

A concrete curtain wall for the CBMS research building was produced at the concrete precast plant of Nesseler Grünzig Gruppe located in the south of Aachen. The concrete used for the façade was mixed from two different aggregates: a segrogran sand was used for the fine aggregate group, while Odenwald granite was used for the coarser aggregate.

The 96 precast elements were suspended using stainless steel façade panel anchors.

The highlight of the façade becomes visible when looking at its cross section. In line with the topic of the research to be conducted inside the building, a structure was created that is modeled on the human X chromosome. The horizontal structure was created as a profiled surface in the form of projecting and retreating lesenes.

The structure was created by means of a form liner which had been previously manufactured from multi-coated wooden materials in the plant’s form-making division and was inserted into the steel formwork. This enabled all of the parts to be manufactured using just this one form.

Visual structuring through surface treatment

Special textures were additionally applied to draw attention to the visual structuring of the façade. The façade was acidified in the area of the peak points, the so-called projecting lesenes. An acidified surface is achieved by removing the uppermost cement paste layer of the concrete surface by means of an acid, thus roughening the surface in an artificial process. Strongly varying effects are produced by varying the intensity of the acidification process. When using this finishing technique, the color of the surface is determined mainly by the ultrafine fractions in the concrete.

In the area of the troughs, the so-called recessed lesenes, the façade of the CBMS building was given a fine washing. To create this surface, the cement paste layer on the concrete surface is prevented from hardening by contact retarders. The non-hardened surface is then “washed off” by means of a high-pressure cleaner. The surface is given a customized washing depth. Interesting light effects ...

Read the full German text in the Beton Bauteile 2018 yearbook (see right).