Soundproofing with innovative lightweight-concrete resonators

The soundproofing of combined heat and power units in block-type thermal power plants is becoming increasingly important. Soundproofed steel sheet containers or concrete sound hoods are used for decentralized plants. Concrete sound hoods are preferably used in residential areas as they offer better soundproofing properties. Manufactured from conventional precast reinforced concrete elements, they achieve masses of around 60 t, which increases the effort required in terms of logistics and assembly. It has to date not been possible to integrate the plant technology at the factory.

In an interdisciplinary project (IAB Weimar gGmbH, Büscher GmbH & Co. KG, Akustikbüro Krämer & Stegmaier GmbH, Eschenröder & Osenberg GbR, AIS Kursawe Anlagenbau & Industrieservice Kemberg), a high-absorption concrete sound hood for improving the soundproofing of block-type thermal power plants was developed which allows preassembly of the concrete sound hood and plant technology.

The development is based on an acoustic concept for a sound-absorbing interior lining. The combination of porous, micro-perforated and selective, resonant absorbers on the basis of an optimized no-fines lightweight concrete results in a reduction of the interior level over a wide frequency spectrum – especially of the predominantly emitted low frequency components between 60 and 250 Hz. The wall thicknesses of the load-bearing concrete were reduced to 80 mm. Location-based requirements are taken into account in the specific design of the acoustic components.

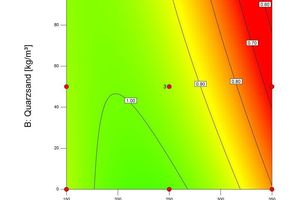

The acoustic absorbers were developed on the basis of lightweight mineral aggregates. The experimental program used expanded-glass and expanded-clay aggregates of different particle sizes, as well as varying percentages of cement paste and silica sand. The related fresh and hardened concrete properties and the acoustic properties in the impedance tube served as response variables. A suitable mix design could be derived by means of numerical optimization.

The frequency-based sound reduction index was determined in the IAB’s wall-testing facility. The weighted sound reduction index RW of previous wall structures could be improved by 9 dB to 53 dB, and the surface-related mass reduced by more than 35 %. The concrete sound hood suitable for preassembly has a weight of under 40 t.