Slide anti-adhesive wear plates filed for patent

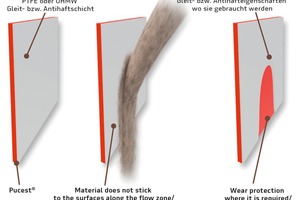

In the bulk materials industry, materials often have to be filled in or discharged rapidly and at high flow rates. The materials are directed to defined impact zones, from where they continue to flow. In this process, material may stick to the surfaces along the flow zones. These surfaces have to be cleaned time and again, which is quite time-consuming and cost-intensive. Moreover, a high degree of wear and tear occurs at the impact zone.

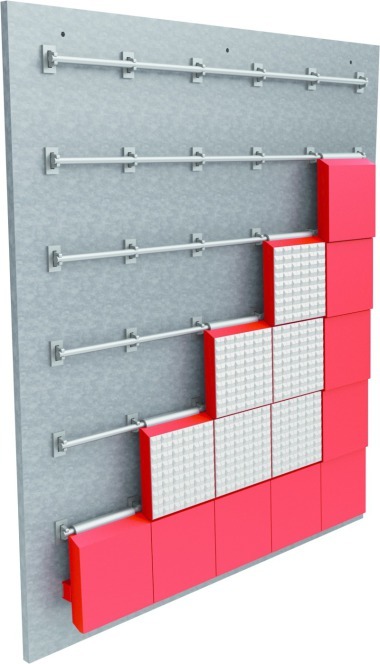

These are the very problems for the innovative development of Pucest protect located in Elsenfeld in Bavaria/Germany, namely their slide anti-adhesive wear plates. The problem of adhesion is solved by the special construction of the slide plates. Moreover, the impact zone is provided with an excellent wear protection simultaneously.

The slide plate filed for patent consists of at least two layers, with a layer made of PTFE or UHMW applied to the Pucest layer. The layer made of PTFE or UHMW, featuring excellent slide and anti-adhesive characteristics, is affected by filling or discharging of materials only at the impact and flow zones of the side plate. The Pucest layer emerging then provides for outstanding wear protection exactly on such spots where it is required.

Different slide surfaces

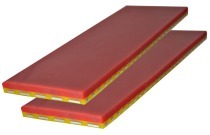

The PTFE slide anti-adhesive plates of Pucest have excellent slide characteristics. They are made of highly wear-resistant Pucest of different degrees of Shore hardness and a coating of polytetrafluoroethylene (PTFE), a fully fluorinated polymer. The UHMW slide anti-adhesive plates of Pucest are conceived for particularly high demands on slide and anti-adhesive characteristics. They are made of highly wear-resistant Pucest of different degrees of Shore hardness and UHMW, an ultra-high molecular weight polymer. These plates feature a very low abrasion coefficient, thus improving the sliding quality without reducing the high degree of abrasion resistance. Therefore, it is almost impossible that bulk materials ingress and adhere.

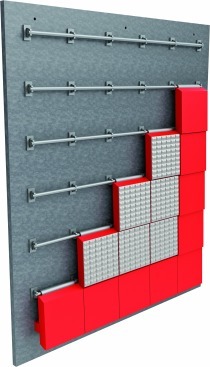

Different versions

Both plate types can be produced as self-adhesive plate with solvent-free adhesive surface, which is ideal for hard-to-reach areas. It is also possible to design both plate types with metal inserts. All types of plates are supplied in a plate size of 560 x 900 mm. The thickness can be chosen from 3 to 20 mm and the Shore hardness from 25° to 90° Shore, according to the customer request.