Set-up for the manufacture of precast concrete parts with a battery form for receiving fresh concrete for forming precast concrete parts

(10) DE 20 2016 006 341 U1

(22) 08.10.2016

(45) 08.12.2016

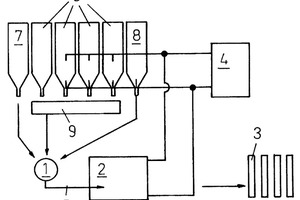

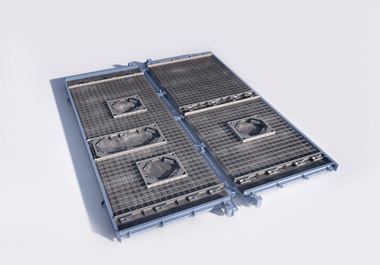

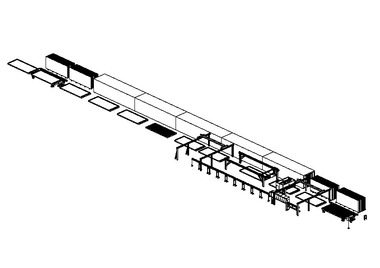

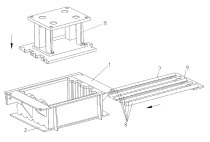

(57) Einrichtung zur Betonfertigteilherstellung mit einer Batterieform (2) zur Aufnahme von Frischbeton zur Ausbildung der Betonfertigteile (3), dadurch gekennzeichnet, dass die Batterieform (2) mehrere beabstandet zueinander angeordnete Schottwände aufweist, dass die Schottwand wenigstens einen Wärmeüberträger (10) besitzt, wobei der durch die nach außen weisenden und beabstandet zueinander angeordneten Wände des Wärmeüberträgers (10) benachbarter Schottwände den Frischbeton zur Ausbildung eines Betonfertigteils (3) aufnimmt, und...