Protection of mixers against wear: Solutions for every application

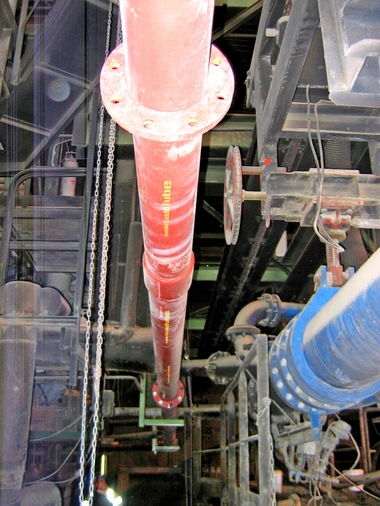

Every mixing and agitation process causes continual wear of the mixer employed. With protective measures the lifetime of the mixer and wearing parts can be prolonged, costs, maintenance and cleaning measures reduced and production losses prevented.

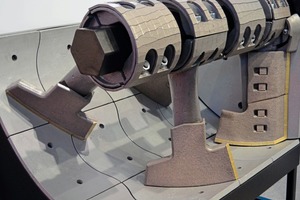

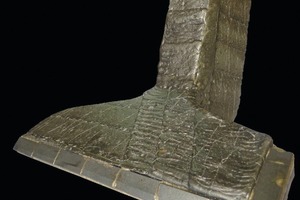

Every mixing and agitation process causes continual wear of the mixer employed. Annular trough or planetary mixers, for example, mix the aggregates with a high intensity through compulsory rotation of the mixing tools in a stationary mixing vessel. Even in normal operation this is associated with high wear, above all in the mixing paddles, mixing ploughs, inner and outer wall scrapers and impact bodies. Incorrect adjustment of the mixing tools can increase wear even more, in addition to creating a poor mixing pattern and thus poor quality of the end product. The energy costs per batch may also...