Production systems for refractory castables continue to grow

Like other „unshaped products“, such as ramming bodies or plastic bodies, castables have seen a steady upswing for decades, while the production of „shaped products“ (largely refractory bricks) has declined proportionately. The manufacturing capacities that are already in place for castables are often no longer sufficient. Accordingly, existing systems need to be expanded or new production systems need to be constructed. In order to manufacture high-quality products, companies often take advantage of the best technology that is available: mixing technology from Eirich.

Eirich mixers for plaster since 1906

In terms of their design and layout, production systems for castables are identical to production systems for factory-produced dry mortar. Systems and mixers for producing brick mortar, plastering/rendering mortar, screed mortar, and tile adhesive are offered worldwide by many manufacturers. Of these, Eirich is the company that has been in the market the longest, having already supplied mixers for plaster as far back as 1906.

The mixing system is the heart of any plant, as it determines the quality of the product. For a single recipe, up to 20 different aggregates, binders and additives (down to the ppm range) need to be mixed in the best possible way. In the case of dry mortars, the very fine materials such as the pigments, lightweight aggregates and plastic fibers present particularly demanding requirements for the mixing technology; with castables, it is likewise the very fine materials and lightweight aggregates as well as plastic or metal fibers.

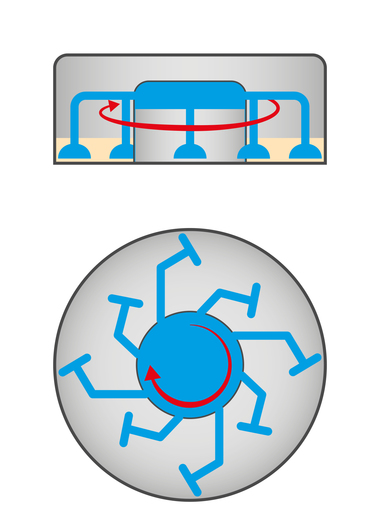

In the main, two different mixing systems are used around the world, both of which generally operate in batch processes. One of these systems is the single-shaft axial mixer, which is also known as a plowshare mixer (derived on its operating principle) and runs with a Froude number below 10. The other system is the Eirich Intensive Mixer. Here, the Froude number – which describes the ratio between the effects of centrifugal forces and gravity forces in the mixing process – can be several times that of the plowshare mixer depending on the application.

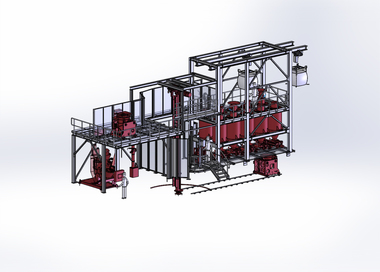

Automated production systems for castables

In addition to the mechanical mixing of the ingredients, the disintegration of fines, deagglomeration and separation of fibers all play a key role. Single-shaft mixers are equipped with additional choppers for this purpose, which are operated at speeds of up to 3,000 rpm. By contrast, thanks to their design, Eirich mixers do not require choppers, as the disintegration of fines and distribution of fines are achieved by the mixing tool thanks to the high Froude numbers.

In order to meet the high quality demands and the large number of different major and minor components that are used, production systems for castables are largely automated nowadays. There are often more than 100 components that are metered via scales, with accuracies of +/-5 g required in some cases. There are also other system-related advantages of the Eirich mixing technology for manufacturers of castables. For example, the efficiency of the mixer does not depend on the arrangement of the product inlets; liquids such as dust binding oils no not need to be injected, but instead can often just be added to the mix; the tool displays less wear, resulting in exceptionally high operational reliability and therefore system availability.

In addition to turnkey plants, Eirich also supplies mixers for optimizing existing systems or for new systems from other plant manufacturers. Individual requirements are implemented in the process. For example, it was a requirement in several cases that the mixer for mixing castables would also need to be able to process brick press bodies and ramming bodies.

In 2016, several more refractory manufacturers awarded orders to Eirich for engineering and supply of the most important parts of a new system (mixer, metering technology, scales, control system). In all cases the award of the order was preceded by tests at one of the test centers, which are available to interested parties at all Eirich sites worldwide.