Precast elements are a perfect match for architectural-landmark retaining walls

The single-span railroad crossing over the Nürnberg – Schirnding railroad line in Hersbruck, in Middle Franconia, Germany, spans Keller Street. The railroad crossing was erected in 1900 with a superstructure of rolled girders in concrete and massive abutments of limestone ashlars. From there, a pedestrian underpass leads to the historical center of Hersbruck and various shopping facilities. Because the old structure was in generally poor condition, the tracks in the crossing had to be replaced to maintain their serviceability.

Athanasios Dosis, Project Manager at DB Netz AG of German Railroads, describes the measure: “In replacing the bridge, we had to take into consideration two particularities: for one, spatial conditions, due to the location in the inner city, were very restricted. Complex shuttering of a new bridge of a cast-in-place concrete construction would therefore have been possible only with great effort and expense. In addition, consideration had to be given to the fact that the retaining walls extending from the bridge in the direction of the inner city are listed as architectural landmarks. Apart from this, we of course always try to keep track possession times that construction of a new bridge involves to an absolute minimum.”

For this reason, the responsible railroad planners decided on a construction of precast reinforced-concrete frames and retaining wall elements for new construction of the tunnel of 18.2-m length (plus retaining walls) from the company Kleihues Betonbauteile GmbH & Co. KG in Emsbüren, Germany.

Precast concrete elements are ideal for use under restricted spatial conditions

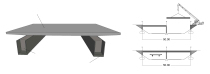

Athanasios Dosis continues: “The advantage of this construction method is that the individual precast frame elements, each weighing approx. 34 to 40 tons (clear width 280 cm, clear height 365 cm, element length 200 cm) could be delivered and erected “just in time,” so that no larger interim storage areas were needed – a particular advantage, given the restricted spatial conditions at the site.” Also important for the planners was that the new construction would be in line with the guidelines of DB Netz AG. This specification was satisfied by meeting the requirements of railroad guideline RiL 804.9040.

How did the erection of the nine precast frame elements, the two portals and the seven inner precast frame elements take place? Athanasios Dosis comments: “The precast elements were lifted and placed with a 500-ton mobile crane. After the soil was exchanged, the precast elements were installed on precast foundations. All precast elements were braced together and grouted. Following placement of the precast elements, they were sealed on the outside in situ with welded bituminous sheeting. Next, the portals were lifted into place and braced together with the seven inner precast frame elements, before finally the wing walls were lifted in place and aligned.”

Precast concrete elements were braced together over the entire length

An important requirement of DB Netz AG for installing precast elements beneath tracks is to design the joints in such a way that no displacements among each other are expected. “For this construction, the individual precast elements were keyed with shear dowels at the joints and additionally braced against each other over the entire length,” explained Athanasios Dosis.

But how did the planners meet the requirement of architectural heritage listing? Dosis continues: “The retaining walls extending from the bridge in the direction of the inner city are listed as an architectural landmark, the bridge itself not. In agreement with the historic building authority and the city of Hersbruck, the walls were cleaned and the exposed surfaces facing the footpath and the wings were provided with a concrete surface in sandstone optics. This solution resulted in a visually harmonic transition from the new bridge to the existing building substance. For us as project management of DB Netz AG, this ensured a construction method with precast concrete elements as the most efficient solution to smooth construction progress with the least possible disturbance of railroad operations.”

The precast elements were installed during a scheduled track possession time in September 2021 by Josef Hell Bauunternehmung from Eltingshausen, Germany. More information at www.kleihues-beton.de.

CONTACT

Kleihues Betonbauteile

GmbH & Co. KG

Siemensstr. 21

48488 Emsbüren/Germany

+49 5903 9303-0