Power Duo connection rail approved for fire walls

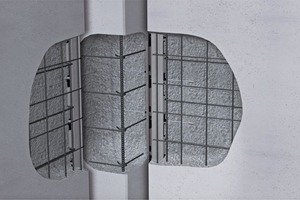

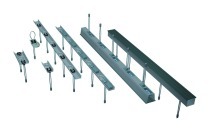

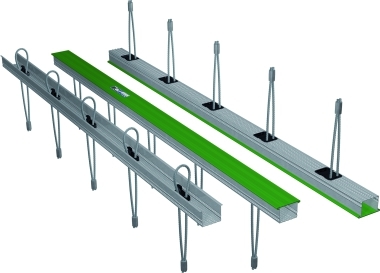

The Power Duo System – successfully used for more than ten years as a simple means for connecting precast reinforced-concrete elements with flexible steel-wire rope loops – has now been approved as equivalent means for connecting non-loadbearing fire walls to adjacent precast reinforced-concrete elements in accordance with the design specifications as per DIN 4102-4:1994-03, sub-sections 4.8.5-4.8.8. In this way, a long-held wish of precast planners has now been fulfilled.

Precast planners, as manufacturers report, widely use rope loop systems, because their properties make them effective for meeting a great variety of requirements, and since their use has accordingly been part of daily practice for many years now. Checking engineers likewise accept approved embedded components of this kind without reservation. Until now, only application systems approved for use in fire walls have not been included in this manner – although it had already been very clear to many that nothing spoke technically against the use of the Power Duo in a fire wall.

Broad range of application opened

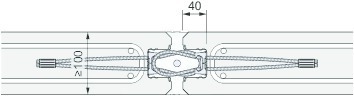

Non-loadbearing fire walls are often used in modern precast skeleton constructions, with the result that the current extension of approval opens up a broad range of applications. For this application, fire walls may be loaded only by their own weight and by additional wind forces acting at right angles to the wall. Connections that must absorb impact loading must be regarded separately as structurally required connections, and must therefore be executed in accordance with DIN 4102-4. Fire walls to be executed with the Power Duo rail must have a thickness of at least 17 cm. Vertical pointing for the rope loop systems should take place with one of six available mortars: either with Betec mortars from Grace or with P&T mortars (in every case either grout or Thixo mortar); the horizontal joints may be executed either as dowel or tongue-and-groove connections and filled with concrete, mortar, or synthetic-resin mortar.

In addition to the use of Power Duo rails in fire walls, experts have confirmed that the system can also be used to meet stricter requirements for fire safety (up to F180). As a result, Philipp, one of the leading manufacturers of transport and erection systems, has begun to close gaps in connection engineering and systematically continues to search for new applications for the construction industry and to meet customers’ requirements in this regard.