“Plastic formwork panels more sought after than ever”

The ongoing Covid-19 pandemic and associated reduced working hours have led to a scarcity of raw materials in many operations. Timber shortage, in particular, could result in delayed deliveries and price increases for conventional formwork panels. Solid plastic panels provide a viable alternative.

Timber shortage causes idle time on the construction site

Plywood formwork panels are one of the consumable products typically used on the construction site. Owing to timber shortage, delivery times and prices are increasing sharply. “In many places, plywood panel prices have risen by over 50% already,” reports Michael Tschenett, Managing Director of Alkus AG.

Alkus AG provides security of supply despite raw material scarcity

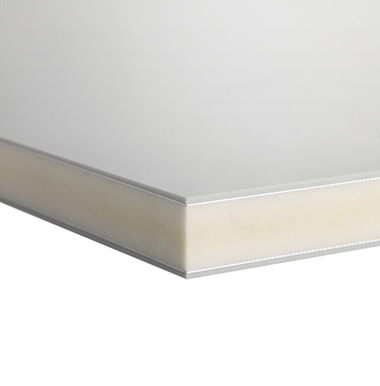

Alkus continues to deliver its solid plastic formwork panels at fixed prices and the usual delivery times of four to six weeks. Although the company is currently experiencing some delivery disruptions for polypropylene and aluminum, the materials the Alkus solid plastic panel is composed of, they have taken the necessary steps and precautions in the supply chain in order to prevent delivery delays.

“You can of course use plywood panels for a longer time if needed, but, owing to the typical disadvantages of wood, particularly its susceptibility to moisture, the panels will become unusable very quickly,” Tschenett explains. “Our Alkus panels last about 30 times longer and have thus been the much more economical solution long before the price of wood went through the roof.”

Trend towards plastic formwork panels

Consequently, the current raw material scarcity accelerates the trend towards plastic formwork panels that began over 20 years ago when the Alkus panel was launched. “Currently, we are definitely seeing a higher demand for our product range,” Tschenett confirms. Alkus is able to ship deliveries to any customer at short notice because their panels fit into any frame.

“Yet the manufacturer does not only profit from the current benefits in terms of availability and price because there is another trend that also favors demand, namely that sustainability is becoming increasingly important – plastic panels are the better solution for environmental reasons because their service lives are considerably longer. Alkus panels have been shown to last for over 1,500 uses, and they can be repaired using identical material. During the same period, contractors would easily end up with using 30 plywood panels, which have to be disposed of as hazardous waste at the end of their service life owing to the concrete adhering to the plywood”, Michael Tschenett adds. “Wood is a wonderful construction material and almost too good to be used as a disposable product for concrete formwork panels.”