News about 3D printing with concrete

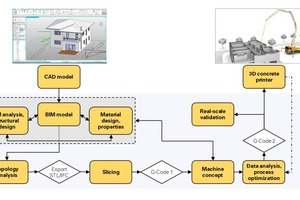

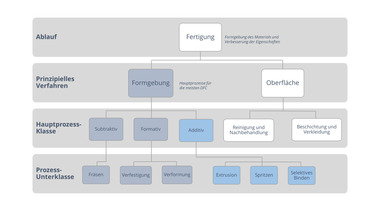

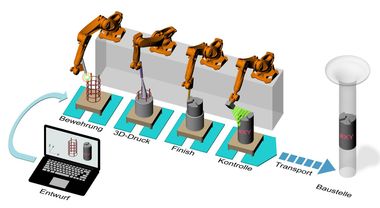

The development of digital concrete printing processes for manufacture of structural concrete components directly at the construction site or in the precast plant is a critical step on the way to introducing the Industrie 4.0 concept in the construction industry. This concept extends from the already existing digital construction planning (CAD, BIM) to digital production. The technological and commercial potential of digital concrete construction has by now been recognized by researchers and by many of the parties involved in construction. The innovation activities in this field are increasing exponentially from month to month. On the one hand, new mechanical solutions for 3D concrete printing are currently being developed. This relates both to the functionalities and the construction of the printhead and the systems for computerized control according to the CAD drawings translated into so-called G-codes. On the other hand, good progress has likewise been made in mastering the rheological behavior of fresh and hardened concrete as scientific basis for designing the printing process. Specific rheological properties, including their targeted temporal development, are required for ensuring sufficient pumpability, extrudability, applicability in the designated construction and manufacturing processes (i.e., dimensional stability during application of subsequent layers), as well as bonding among the individual layers.

In these efforts, control of the thixotropic properties and the hydration kinetics of fresh concrete as well as correlation of the rheological behavior to the operating parameters of the digital production process play a crucial role and take due account of machine engineering. The lecture provides an overview of the latest developments and assesses them critically. In addition, it reports on the activities of the new RILEM Technical Committee for Digital fabrication with cement-based materials. The Committee began its work in 2016 and has addressed aspects concerning state-of-the art digital manufacture in concrete construction.