New welding machine technology for standard mesh, customized mesh or industrial mesh

The „PL AKK“ series wants to set new standards in the production of construction reinforcement meshes, customized mesh (so called Listenmatten) and industrial meshes (fences, gabions, single and double rod meshes, etc.). The Avant-Garde concept eliminates all changeover times and significantly increases productivity compared to conventional welding machines. On machines with one coil per each line wire, each coil change costs time. This downtime adds up significantly. The AKK is designed to avoid exactly this. While only one coil is working for the line wires line and one for the cross wires, a second coil is in a waiting position and can continue working as soon as the first coil is finished. This system of redundant line and cross wire unwinding stations with single coil wire feed makes the not flexible long coil rows of conventional welding machines unnecessary.

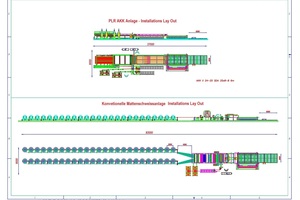

The innovative design of the PL AKK series enables automatic mesh pitch and dimension changes, making it the only flexible coil-fed mesh welder for high production rates. All mesh types can be produced immediately and without any changeovers. Thus the PL AKK machines offer a compact system layout with minimal space requirements.

No changeover times when

Changing coils

Changing the line and cross wire pitch

Change of the mesh dimensions

In addition, the patented wire feeding system allows diameter changes without loss of time or production. It only takes a small fraction of the time compared to conventional mesh welding lines. The patented „Automatic Wire Orientation System“ (AWOS) enables the use of a high-speed roller straightening unit for line wire feeding and compensates the straightening errors of the roller system. Due to the flexibility of the AKK welding machines, there is no need to store large quantities of finished mesh, as is the case when using conventional welding systems. The PL AKK system is designed for the processing of cross and line wires from coil of up to 12 mm. The machines of the PL AKK series are also available in versions for processing coil material of up to 6mm, 8mm or 10mm. Numerous systems are already being used in Europe, the USA, Turkey, Japan and South America.