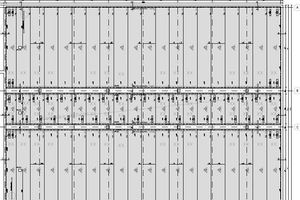

New construction concepts for Hamburg‘s schools as an example of modular construction

„Hamburger Klassenhäuser“

Hamburg sees a growing number of pupils. In order to meet the increasing need for classrooms, the SBH Office for school construction of the City of Hamburg (Landesbetrieb SBH | Schulbau Hamburg) has developed a modular construction concept for the extension of school locations. This concept takes various demands for space ranging from 900 m² to 1,800 m² into account. The specifications required a sustainable system for new buildings with a high level of flexibility and fast planning and construction processes.

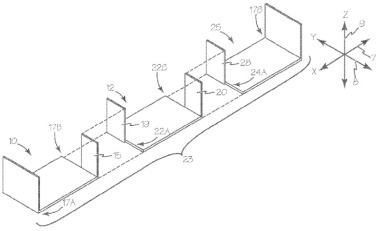

Center piece is a modular load-bearing structure

A modular load-bearing structure with an individual basic structure is the center piece for the successful implementation, allowing for adaptable floor plans and a wide variety of extension options. Another important advantage of this modular construction system are significantly shorter construction periods, with specifications stipulating nine months between start of construction and completion for the „Hamburg School Buildings“ („Hamburger Klassenhäuser“).

The design is worked out in close consultation with the schools: no matter whether wood, clinker bricks or plaster – the façade and windows will be gently adapted to the neighboring existing buildings. High-quality materials with a long service life shape the sustainable character of the new buildings which are aiming at a minimum service life of about 80 years.

Minor disruptions in school operations

„The high level of prefabrication assures short construction periods with a reliable quality and as little disruption of the ongoing school operation as possible,“ reads a quote from the press release of the SBH website at www.schulbau.hamburg.

Otto Wulff Bauunternehmung GmbH

The first approx. 19 school buildings with an NFA of approx. 20,000 m² have already been completed, additional 36 elementary schools with an overall NFA of 32,000 m² will be implemented by the end of 2024.

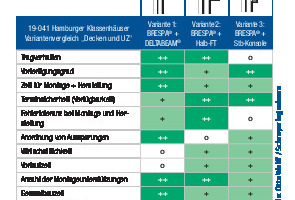

In 2020, Otto Wulff as general contractor built six of the first eight school buildings; five additional schools are in the completion stage and a contract has already been awarded for four additional ones. The construction works for the first six schools started in June 2020 and keys were handed over in January 2021. „After internal technical verifications, we launched external studies on the load-bearing structure,“ explained Dipl.- Ing. Pawel Kampa, head construction manager and responsible project developer of the modular load-bearing structure installed in the Hamburg School Buildings of Otto Wulff. „Together with the Bad Oldesloe-based engineering office Schreyer Ingenieure, our technical office has proposed – after the evaluation of all relevant criteria – to use a floor system made of precast prestressed concrete floor slabs and flush composite beams as supports in interior areas.“

Comparison of variants suggests precast prestressed concrete floor slabs

The main advantages of this slim-floor construction are:

fast construction progress,

resource-conserving construction method,

adherence to schedules and high level of prefabrication,

large spans with adaptable floor plans as a result,

even, undisturbed soffits and

cost-effective floor system.

Additional five school buildings of the third tranche with an overall NFA of 6,525 m² will be completed by Otto Wulff in 2022 within eleven month (planning + construction) using this construction method.

Interview

The BFT editor-in-chief interviewed Dipl.-Ing. Pawel Kampa, head construction manager at Otto Wulff Bauunternehmung GmbH and project development at Otto Wulff for the „Hamburg School Buildings“, on the above-mentioned construction project and on the development of modular construction on the whole.

BFT International: Mr. Kampa, has modular, serial construction a future in Germany and can it achieve the acceptance as among our European neighbors?

P. Kampa: Yes, because the fast implementation due to a high level of prefabrication, planning completed before the start of construction, clear processes and a small, coordinated team on the construction site clearly speak in favor of a modular construction.

BFT International: What exactly must happen in this regard?

P. Kampa: Answer: Helpful for a development in this direction is the support of public authorities and municipalities as for the Hamburg School Buildings. The City of Hamburg and the schools, for example, have recognized the advantages in terms of time and efficiency. Further school locations are already in the planning stage in Hamburg. At first, this modular construction concept shortens the approval procedure and then the construction period, thus providing the required school space very fast.

BFT International: The first school buildings have been completed. How is the field report?

P. Kampa: Very positive! The users, the SBH and we ourselves are very satisfied with the school buildings constructed. We have managed to complete the school space on schedule, on a turnkey basis.

The considerations we had made in respect of the construction and the overall construction process have proven to be correct and good.

Our specialist contractors are very satisfied too. The modular construction implemented by us using prefabricated precast elements facilitates the production of the structural components because the requirements remain identical. Thus, our specialist contractors express great interest in further cooperation.

However, together with our client, we have realized that we have to discuss more intensively on site about the planning processes, logistics and implementation of construction works. A continuous dialog is imperative.

BFT International: The hallways were yet provided as semi-precast floor slabs in the first considerations, but eventually they were designed as precast prestressed concrete floor slabs. What were the reasons for this?

P. Kampa: Above all the fast implementation process with as few interfaces as possible. We were able to facilitate planning through the adaptation of the construction and/or statics as well as the uniform floor slab design and optimized the interfaces between production and implementation of construction works.

BFT International: Mr. Kampa, many thanks for the conversation und much success furthermore!