New circulation system installed in Moscow region

The Russia group of companies SU-155 increases output and quality of their precast concrete production with the aid of a new modern circulation system for solid concrete and sandwich elements of Vollert. At the same time, the high flexibility of the plant provides the company a wide range of possibilities for architectural design.

Michail Balakin, the SU-155 group’s chairman of the management board, sums up the key advantages on the occasion of the official opening of the plant in November 2014: “The new production line signifies a breakthrough in industrialized residential construction because it enables us to manufacture individual homes by means of precast construction. The second advantage is the high quality of the precast concrete elements allowing us fast and cost-effective construction of high quality simultaneously. And the third advantage is the fact that the new plant technology has an eight times higher capacity than the old one.”

A string of

modernization measures

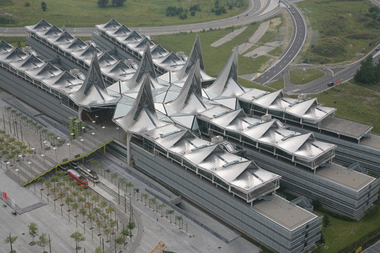

The new circulation system installed at the ZAO Strojindustrija location in Odintsovo close to the Moscow Vnukovo airport ground is the first of a whole string of modernization measures taken by the SU-155 group. The system is based on the consistent technology platform of Vollert plants associated with a central control system of Uni-technik. Furthermore, SU-155 will use the CAD/BIM software of Tekla for building modeling in future. These fundamental data will be directly integrated in the control system of the plant.

In this way, the Russian construction group will get quite new options regarding the distribution of capacities, because the production data needed can simply be transferred to the different production sites. “The data created by the project department even contain all control information for the production line besides information on the geometry of the concrete element, that is to say what has to be produced first, in which output quantity and in which order. Thus, the production cycle from the idea of the architect to starting production in the factory is reduced to a fraction allowing us to realize diversified projects,” explains Michail Kosolapov, General Director at ZAO Strojindustrija. This is supported by the high flexibility of the plant, the circulation systems of Vollert are equipped with. A quick change of the manufacturing process from one product to another is hence possible.

High level of flexibility in the production process pays off

The shuttering robot Smart Set of Vollert is playing a special role here. Its high degree of precision when placing the shutters weighing up to 250 kgs and when plotting the embedded parts allows manufacturing of precast concrete elements with tolerances of just 1 mm. The use of flexible shuttering systems moreover allows the company to manufacture new concrete elements at any time without the effort of any changeover. In addition, the circulation system comprises all work stations of the production line, such as the concrete spreading unit, the shaking and vibrating station for concrete compaction, a curing chamber with storage and retrieval unit as well as the plant technology for surface treatment. Options for later expansion have already been taken into account as well. Furthermore, the own mechanical engineering factory of SU-155 locally manufactured 100 circulation pallets under the direction of Vollert.

“The plant‘s high degree of flexibility pays off already now,” points out Sergej Lapyrev, General Manager at OOO Vollert RU. “At the beginning of the planning process, we yet considered the production series typical by then. In the meantime, ZAO Strojindustrija is however realizing a production program comprising a new series of house designs without any changeover. Leading European architects designed these series for SU-155 as part of a partner program.” The precast concrete elements are destined for the project FlightCity of the Spanish architect Ricardo Bofill. The building complex in the vicinity of Moscow covers a living space of approx. of 145,000 m² consisting of ten differently structured eight-story buildings.