New cement types

The cement portfolio of the Holcim Deutschland Group was supplemented by several new high-performance products. Thus, the building materials supplier is optimizing the product range, adapting it to the requirements of customers and markets. Main focus in the development of the new products was on the issues of sustainability and efficiency.

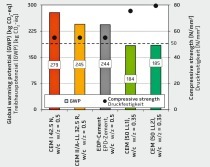

Holcim even launches two new products for the production of precast concrete components: With Holcim Duo 5 Premium from the Dortmund factory Holcim offers a blast furnace cement of strength class 52.5 R for the first time. This cement enables manufacturers to use a product that is highly environmentally friendly and sustainable even as far as applications with the highest demands on early strength are concerned. The same applies to the new Holcim Fluvio 5 R, a Portland limestone cement from the Höver factory, which can be used as an alternative to pure Portland cements too. In respect of the processing characteristics as well as the appearance of the concrete surface, both new cement types are excellently suited for the production of precast products.

Reduced development of heat

Holcim Aqua 80 manufactured in Dortmund is a special cement with optimized properties in respect of sustainability, durability and the development of heat. The content of blast furnace slag is reduced to the maximum allowable amount according to the standard for CEM III/B. Consequently, this cement features a particularly favorable carbon footprint. Especially in the Dutch market such binders are in high demand today. The cement is especially suitable for the production of solid structural components as the heat development has been reduced to a minimum.

By Holcim Fluvio 4 N a Portland limestone cement of strength class 42.5 N supplements the product portfolio of the cements offered in bags by the Holcim Deutschland Group. This cement type is in high demand among manufacturers of cement screed and was especially conceived for this application.