B. Lütkenhaus GmbH from Dülmen is expanding climate-friendly production step by step - with cement from Holcim

In fact, Ulrich Lütkenhaus would not have to change anything: With more than 1 million m² of precast wall units and floor slabs produced per year, the Dülmen-based B. Lütkenhaus GmbH managed by him is one of the most efficient and innovative concrete and precast plants in Germany. However, only family-run companies which are prepared to change in the course of time, will be able to look back on a tradition of more than 100 years.

And for Ulrich Lütkenhaus, cutting CO2 emissions is an important reason for further developing: „For us, the subject of climate protection significantly gathered momentum and the demand of contracting authorities, clients and building contractors for environmentally friendly products and solutions is rising sharply,“ the managing partner states.

Climate-friendly solution

When Holcim Zement sales representative, Werner Bilbang, presented the Holcim Duo 5 Premium blast furnace cement at B. Lütkenhaus, they showed great open-mindedness. Because this cement is suited to the sustainable production of high-quality precast concrete elements.

Cements with high early strength are required for the manufacture of precast concrete products. This ensures that a high output rate is achieved in the manufacturing process and high quantities as a result. Conventional Portland cements with high strength development make it possible.

Therefore, B. Lütkenhaus has been supplied with the Portland cement Holcim Pur 5 Premium (CEM I 52.5 R) until now. Due to the process and due to the raw materials, the production of Portland cement clinker leads to a not insignificant amount of CO2 emissions. The CO2 footprint of the cement is reduced, for example, by replacing portions of the clinker by granulated blast-furnace slag – then, this is called blast furnace cement (CEM III).

Tested with success

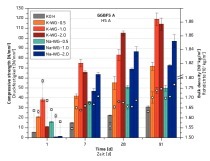

„Since the blast-furnace slag needs the clinker as an „activator“ for the strength development, the strength development of such type of cement is slower. As a consequence, especially blast furnace cements are produced with a normal strength development and not a fast one, and they are well placed in the market,“ Werner Bilbang explains.

The cement was adjusted in close coordination with B. Lütkenhaus as well as their supplier of admixtures. Before large-scale technical tests were carried out at the Dülmen facility of Lütkenhaus, tests on the strength development of the cement at different temperatures took place in the application laboratory of Holcim in Dortmund. Outcome: The early strengths after two days exceed those of a Portland cement of strength class 42.5 R. „Using Holcim Duo 5 Premium, we were able to meet the high demands on early strength required by the precast industry – while reducing the CO2 emission in the production by about 33 % as against conventional CEM I 52.5 R,“ states Helmut Eckhardt, Holcim Product Manager Cement.

„Since August 2019, we have been substituting a portion of the Portland cement in our production by Duo 5 Premium cement. For this purpose, the cement is replaced at a ratio of 1:1. Hence, we do not use more cement,“ Ulrich Lütkenhaus explains. „We are absolutely satisfied with the outcome and we can imagine to extent the portion of blast furnace cement even more.“

The cooperation based on trust and partnership is the basis of this success story. „After additional tests, we are convinced at Holcim that the early strength can be increased even more with the aid of appropriate concrete admixtures,“ Werner Bilbang states.