National Green Plant certificate for pigment production in Ningbo

Lanxess, the specialty chemicals group, was recently awarded the National Green Plant certificate for its plant in Ningbo, China, by the Ministry for Industry and Information Technology (MIIT) of the People’s Republic of China. The Lanxess plant, which is rated on a national level as one of the Top 3 facilities, is located in the Ningbo Petrochemical Economic & Technology Development Zone (NPETD), on China’s east coast.

This certification is a significant element of China’s so-called Green Manufacturing System. Its objective is to accelerate industrial development in China, while adhering to a high environmental standard. The Quality Seal is awarded to only one thousand Best-in-Class companies, which, in their respective segments of industry, have made a clear commitment to sustainability by means of cutting-edge technologies and environmentally friendly processes at their production sites. “Our plant in Ningbo sets a new standard for China’s pigment industry and wins high marks with good, above-average values. This applies in particular to its low pollutant emission and low energy consumption, as measured per ton of product,” says Holger Hüppeler, Manager of the Inorganic Pigments Business Unit (IPU) at Lanxess. Hüppeler, who now, after succeeding Jörg Hellwig in this position in December 2018, vigorously and cross-departmentally promotes the digital activities of the Lanxess Group.

Ningbo reduces harmful emissions

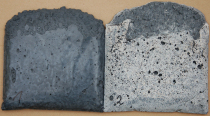

In its certified cutting-edge plant, Lanxess uses the Ningbo process that it developed for manufacture of synthetic iron-oxide pigments. The production method is based on patented technology and enables the currently most environmentally friendly production of synthetic iron-oxide pigments in Asia in the medium color range and in the red range with a yellowish color cast. Compared to the traditional Chinese iron-oxide red process, notably fewer nitrogen oxides, such as extremely harmful nitrous oxide, are emitted. A highly efficient secondary treatment stage, moreover, completely removes the remaining greenhouse-gas emissions.

“In this way, Lanxess demonstrably contributes to environmental protection. The Penniman process, which in China is primarily used for production of red iron-oxide pigments, annually produces unfiltered nitrous oxide at the annual rate of around 7.6 million tons of CO2 equivalent. If all of these Chinese production facilities would use our Ningbo process, this would correspond to the reduction of greenhouse gas by the annual CO2 emissions of 300,000 Chinese households,” says Hüppeler.

Right on schedule

With its 13th Five-Year Plan for the years 2016 to 2020, China is developing renewable energies and enhanced utilization of resources to reduce environmental pollution. The target set by the government itself to promote the Green Manufacturing System is part of the industrial modernization program “Made in China 2025,” to catch up with the leading industrial nations. Stricter environmental requirements, for example, are scheduled to reduce CO2 emissions by 22 %, energy consumption by 18 %, and fresh water consumption by 23 %. The industry’s principal pollutant emissions (SO2, NOX, CSB) are targeted for reduction by 20 % until the year 2020.

The National Green Plant certification program launched by MIIT in April 2017 is one of the prerequisites for meeting this objective. Companies that apply for it must comply with the Environmental Protection, Safety, and Energy-Saving Regulation and must operate without an accident for a prescribed period of time. The Economy & Information Commission reviews submissions and recommends the best applications to the MIIT, at which the final review takes place. “In the qualification process for 2018, a total of 460 companies passed the preliminary review by the local Economy & Information Commission, and their applications were passed on to the Ministry for final review,” emphasizes Hüppeler.

Lanxess stands out

In the next step, the applicants must demonstrate their leading roles in implementing the highest environmental standards in their segment of industry. So far, only 200 companies have received these certificates in 2018. “The Lanxess Plant in Ningbo has qualified for certification by fully meeting the high standards of National Green Plant certification. That means, among other accomplishments, conformity with all laws and regulations in China, as well as notable reduction of energy consumption and CO2 emission below the average of the respective industry. Furthermore, our raw materials consumption per product ton is the lowest within the Chinese iron-oxide industry,” says Hüppeler.

The advantages for the bearers of the National Green Plant certificate are – apart from the enhancement of reputation – simplified credit policy and approval of new projects, as well as fewer inspections by the authorities. “What’s more, we are until now the first global iron-oxide manufacturer certified as based on National Green Plant requirements,” says Hüppeler. “This makes us stand out from our competitors, since other companies will have to redesign their systems or processes with a view to sustainability and improved environmental protection standards, in order to succeed in China over the long term.”

The IPU business unit of the Lanxess specialty chemicals group is the largest global manufacturer of iron oxides and one of the leading producers of inorganic pigments based on chromium oxides. Locations are in Krefeld-Uerdingen in Germany, Porto Feliz in Brazil, Starpointe Burgettstown in the USA, Branston in Great Britain, Vilassar de Mar in Spain, Sydney in Australia, and Shanghai and Ningbo in China. The IPG business unit belongs to Lanxess Segment Performance Chemicals, which achieved in 2017 a turnover of EUR 1.44 billion.