Mobile dry weather flow channel for increasing the hydraulic performance

Subsequent adaptions for increasing the flow rate in the existing sewer system also necessary in the North Rhine-Westphalian state capital of Düsseldorf because of the declining water consumption. For the optimization measure, the municipal sewage works the client opted for mobile concrete elements, so-called sewer bottom blocks.

Rising environmental awareness, the desire for saving energy and conserving resources lead to the fact that more and more people save water consciously. At the same time, longer dry weather periods occur in many places more frequently with the result that many sewer systems have to be adapted to the related requirements. Because the reduced volumes of wastewater have an impact on the transport behavior of the entrained dirt particles which facilitate unwanted sediments. Owing to the poorer drainage of wastewater a considerable sedimentation of the dirt load may arise within a very short time. The consequences are not only unpleasant odor caused by decay, but also corrosion of the building materials. For one thing, this requires time-consuming cleaning works and cost-intensive maintenance of the sewers in the long run.

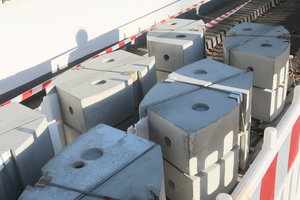

Subsequent adaptions for increasing the flow rate in the existing sewer system were also necessary in the North Rhine-Westphalian state capital of Düsseldorf because of the declining water consumption. It should be achieved by reduced flow cross-sections in the bottom area. Narrowing the bottom (dry weather cross-section) results in a sufficient limiting depth, ensuring the transport of dirt, even in case of fewer water inflow. Nonetheless, at the same time, the maximum possible water drainage is guaranteed without backwater, even in case of changing hydraulic requirements with large run-off volumes – keyword heavy rainfall events. For the optimization measure, the municipal sewage works of the state capital of Düsseldorf (SEBD – Stadtentwässerungsbetrieb Düsseldorf) as client opted for mobile concrete elements, so-called sewer bottom blocks. These are solid interlocking precast blocks which are laid on the bottom easily and inexpensively, thus being installed in an existing sewer as dry weather flow channel, in order to increase the flow rate there and to avoid sediments.

Berding Beton with its DW Nievenheim factory was found as development partner for the sewer bottom blocks and supplier of the same. Berding Beton not only has more than 30 years of experience, but is above all known for its innovative potential and the tailor-made product solutions. Thus, in this case again the idea of the SEBD municipal sewage works was discussed according to the client‘s request, in order to find the best solution in terms of design and development of the mobile construction elements for improving the wastewater transport.

Special interlocking precast elements

The basic concept: The dimensions of the sewer bottom blocks are designed so that they can be installed easily as mobile elements through the normative manhole opening (diameter of 62.5 cm). Therefore, neither a classical construction site with excavation pit nor opening of the sewer are required, eliminating disruptive impacts on the urban transport network.

Moreover, the special interlocking precast elements score with their high flexibility. They can be installed in ongoing operation so that no dewatering or water management is necessary. The substantial difference to conventional, permanently installed dry weather flow channels: It is not a permanent installation but a mobile system that can be modified or can be removed completely through the manhole again if hydraulic requirements change. Due to their high self-weight and the reliable interlocking among each another, the system ensures that the precast concrete elements neither move nor shift on the sewer bottom. The design as a modular system allows for the realization of the requested dry weather flow channel in any length.

Based on the good experience gained with the use of the sewer bottom blocks as T-shaped concrete elements in collectors with rectangular profiles, the desire arose on the part of the SEBD municipal sewage works to have sewer bottom blocks which can be used in circular sewer cross-sections, too. An innovative feature that required quite a lot of creativity and know-how in construction owing to the change of profile from a horizontal bottom to a circular cross-section. Because all above-mentioned advantages should remain ensured for an arrangement on a round sewer bottom as well – for example, that individual interlocking precast blocks will not detach even in case of large run-off volumes and the related force acting on the building components. The product development again took place as a joint project between the municipal sewage works of the city of Düsseldorf and Berding Beton.

Many advantages of the precast elements made of reinforced concrete

Initially, first sample components were tested in a pilot project intensively under real operation conditions with all runoff-related water levels and flow rates in situ. After the successful completion of the tests, the first precast concrete elements were used for round cross-sections in the sewer system in Düsseldorf. Without any problems, 200 rounded sewer bottom blocks – with a single length of 916 mm, a width of 285 mm, a height of 400 mm and a unit weight of 180 kilos – were installed in a circular cross-sectional profile of DN 2500, showing a curve shape with a radius of 35 meters, among others. All blocks were mounted on a system securing the position. The construction work was carried out in existing context and in full operation.

Apart from the above-mentioned advantages of the sewer bottom blocks, such as high flexibility in handling compared to permanently installed special cross-sections and above all the possibility of a subsequent installation including shearing protection among the precast elements, the material provides substantial benefits, too. Precast elements made of reinforced concrete feature a uniformly dense and smooth surface for ensuring the flow rate required as well as a high quality and dimensional accuracy. This means that, with the aid of sewer bottom blocks for circular cross-sections, precast dry weather flow channels can increase the hydraulic performance of sewer systems in a fast and easy way as well as an efficient and high-quality manner. High flexibility is also provided in terms of installation: Work can be interrupted at any time because of the weather, being continued afterwards without any problems and without further preparations. It is moreover a big advantage that the innovative sewer bottom blocks can be installed in almost any existing sewer but also in newly planned sewer systems, because Berding Beton offers the precast concrete elements in customized shape designs along with the standard versions.

On the occasion of an on-site visit of the sewer in November 2020, together with Hans-Georg Müller and Gregor Jarosch of Berding Beton Nievenheim, Michael Schoppen and Peter Albrecht of the SEBD municipal sewage works convinced themselves personally of the outcome. „After the completion of a project, it is also important to us to see whether everything works in practice as planned and whether there is still potential for improvement at one point or another. In this regard, one gets of course the best impression on site,“ the gentlemen, who were very impressed by the implementation completed by the skilled personnel, agreed unanimously, „they achieve an enormous work under the special conditions here in the sewer system.“

CONTACT

Berding Beton GmbH

Industriestr. 6

49439 Steinfeld/Germany

+49 5492 87-24