For extreme conditions of use in practice –

The development of high-strength and ultra-high performance concretes (UHPC) has been discussed among experts and promoted for several years now. The short term UHPC refers to concrete grades with material properties being significantly higher than the standard values, for examples, of the German standard DIN EN 206-1. The concrete types made of UHPC offer a wide range of new and filigree construction possibilities providing a high load-bearing capacity and slender cross-sections. Apart from numerous theoretical surveys and the corresponding research projects, practical applications are gaining more and more importance. Bridge structures, façade elements or stairways with considerably reduced cross-sections have been realized successfully in the last few years. In most cases, these however were project-related applications with a scientific background. So far, we do not known much on the purposeful manufacturing of UHPC building components made in industrial full-scale production, although there are promising approaches with UHPC here too.

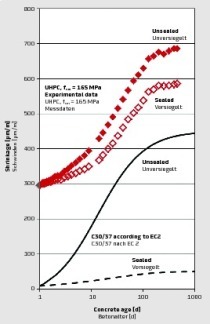

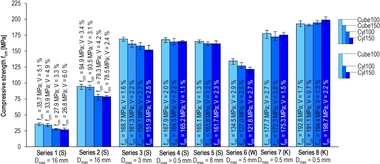

The basic principle of the manufacturing of high-performance concretes is based on the approach of minimizing the capillary pores in the concrete structure by very densely packed ultra-fine components in combination with a very low water/cement ratio. Besides the classical constituents of a conventional concrete mixture, for UHCP other fine materials (e.g., silica dust, stone powder, or the like) and appropriate additives are added in order to obtain an as high density of the matrix as possible. In this way, it is possible to achieve compressive strengths in the range of 100 up to 200 N/mm². Experts, however, have realized in the meantime that the compressive strength alone does only provide limited approaches for practical applications. In particular, the brittleness of the original UHPC concretes caused problems which primarily resulted in a higher risk of cracking and the correspondingly negative impacts. For this reason, modern UHPC research pays more attention to the development of UHPC concretes with optimized material properties, comprising a high compressive strength, high bending tensile strength and a reduced modulus of elasticity. These UHPC concretes are characterized by a high tightness and durability and they are therefore excellently suited to the production of precast concrete elements in civil engineering and road construction.

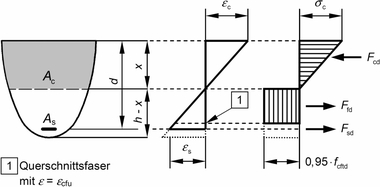

In practice, sewerage systems made of concrete and reinforced concrete are subject to many requirements. They have to be tight, durable and designed for static and dynamic loads. The very long depreciation periods, in particular, in the field of municipal sewer construction require building components with a life span of more than hundred years. Building components made of concrete and reinforced concrete are already in the position to meet these requirements to a large extent, even without UHPC; there are, however, limits when it comes to the chemical resistance and the static load-bearing capacity. Using UHPC for the manufacturing of such precast concrete components gives rise to new approaches that may contribute to significantly improved properties of the finished product. Due to the dense structure, UHPC is at first virtually impermeable to liquids, gases and chlorides allowing new applications in environments aggressive to concrete. Apart from that, for building components made of UHPC concretes there are new calculation models in the field of structural design resulting in advantages due to slender components and smaller wall thickness respectively. This allows manufacturers to realize pipes used for difficult installation sites with very low or very large covering that do not require time-consuming additional measures (e.g., concrete supports). UHPC precast components provide promising approaches also for building components that are subject to high loads caused by dynamic traffic loads (e.g., at airports).

Using several practical examples, the presentation gives an overview on the application of UHPC concretes for the manufacturing of precast components, pipes and drainage channels used in demanding projects with special requirements.