Elements with non-metallic reinforcement – Shear model for members with and without shear reinforcement

Non-metallic reinforcement made of fiber-reinforced polymers (FRPs) features high tensile strength and excellent resistance to corrosion. Existing models for predicting the shear resistance of FRP-reinforced elements were derived for solid cross-sectional

dimensions similar to conventional steel-reinforced structures, which is why their application to thin slabs in the thickness range from 30 mm to 200 mm with high-strength FRP reinforcement is debatable.

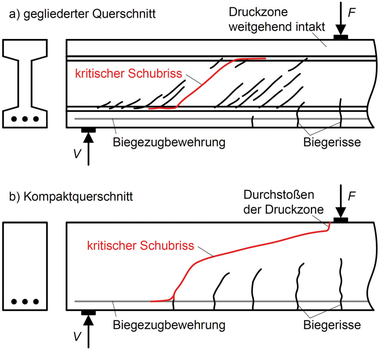

A unifying perspective on the shear capacity of FRP-reinforced elements is taken with a new additive shear model. It covers a wide range of member geometries and reinforcement types and is equally suitable for FRP rebar and FRP textile reinforcements. Combining

the results of 144 own tests with studies on FRP-reinforced specimens

from the literature in two databases created the basis for calibrating

and validating the model. To determine the concrete contribution to shear resistance, an established semi-empirical model was extended

by a shear slenderness factor and modified in its size effect factor. A rotation-based approach is proposed for predicting the reinforcement

contribution that explicitly accounts for shear compression failure by means of variable strain limits for the vertical reinforcement that depend on the local strain state of the longitudinal reinforcement. The results obtained with this model show excellent agreement with the database. The model represents an important step towards future applications of FRP reinforcement in various structural systems,

cross-sectional geometries, and loading situations, and enables to leverage the advantages of construction with this

innovative material.