Durability properties

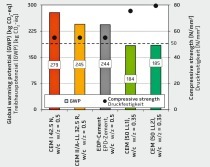

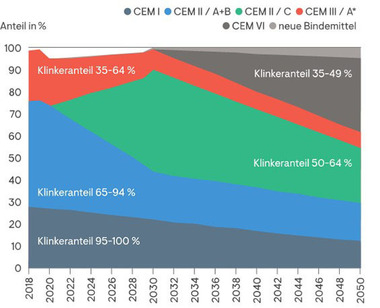

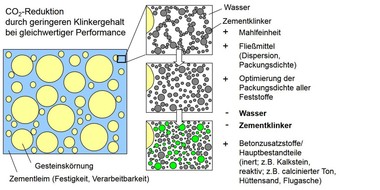

In the next version of DIN EN 197-1, additional standardized clinker-efficient cements will be added with CEM II/C-M and CEM VI. CEM II/C-M cements contain at least 50 M.-% clinker and CEM VI cements, at least 35 M.-%. Other main constituents are limestone, granulated slag, flyash and pozzolan. Various research projects of the German Cement Works Association (VDZ) have investigated the properties of mortars and concretes for which these cements were used.

This presentation investigates the properties of fresh and hardened concrete, as well as durability properties of concretes made with CEM II/C-M (S-LL) cements from these projects, and discusses further literature sources. Where possible, the results are compared based on the assessment criteria common in Germany and/or on comparison with the properties of concretes – for example, with CEM I or CEM III/A (reference concretes). The presentation, in addition, includes results of investigations performed with CEM II/B-LL cements. CEM II/B-LL cements are already contained in DIN EN 197-1, but were until now used in Germany only in a few cases in the structural sector. Given the availability of raw materials, they may possibly become more significant. These data enable assessment of the possibilities of application of CEM II/C-M (S-LL) and CEM II/B-LL cements that depend on exposition.

The evaluation of own investigations and of literature data show that CEM II/C-M (S-LL) cements and, possibly also CEM II/B-LL cements, satisfy at least the essential requirements placed on the properties of fresh and hardened concrete for interior and exterior structural elements.

CEM II/C-M (S-LL) cements and CEM II/B-LL cements have the potential for application in many areas of concrete construction in Germany, both with regard to their technical properties and their availability for manufacture of the necessary constituent materials, thereby contributing in this way to reducing CO2 emissions in concrete construction.