DBV Code of Practice “Injection hose systems and swellable fillers for construction joints” – Additional applications

The new December 2020 version of the DBV Code of Practice on “injection hose systems and swellable fillers for construction joints” [1] again aims at planners, contracting parties and building contractors. It provides information on planning and the invitation to tender, work process planning and the material selection for injection hose systems and swellable joint fillers and provides application guidance in respect of execution and quality assurance and gives examples concerning the documentation of the works performed.

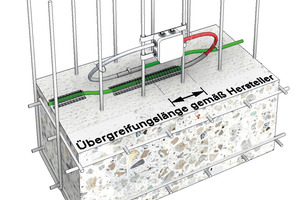

Injected hose systems and swellable joint fillers only bind partially to the structural concrete of the second concreting section. The crucial requirement for the successfully sealing effect of an injection hose system after an injection, among others, is the surface contact of the joint filler in the construction joint. In this regard, amendments were added for a permissible joint roughness in the immediate contact area of the hoses.

Extended scope of application

In addition to the consideration of experiences and product developments of the last 10 years, the declared intention of the Federal Waterways Engineering and Research Institute (BAW – Bundesanstalt für Wasserbau) and DBV to include various fields of application for injection hose systems in a jointly revised DBV Code of Practice that is ZTV quotable was one reason for the revision and amendment of the DBV Code of Practice of 2010. Hence, the most important latest topics include the addition of a section on engineering structures, which are covered by Additional Technical Conditions of Contract and Guidelines for Engineering Structures of the public transport modes ‘road’ (ZTV-ING) and ‘water’ (ZTV-W). Therefore, for example, amended requirements for general building supervisory test reports were laid down in the scope of application of public transport modes (abP-ZTV).

The new Annex D will stipulate requirements and characteristics of hose fillers which shall be observed and complied with in an invitation to tender and when testing the technical documentations of the manufacturers. Most of the drawings were converted in

3D (Fig.) to improve the clarity of the layout.