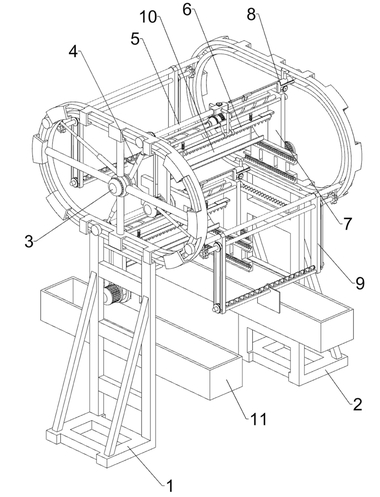

Crust Cracker

The Crust Cracker is a newly developed cleaning and reconditioning system for all types of concrete block production boards made of steel, plastics or wood. It is a self-contained and automatically controlled system that can be integrated into existing production lines, as an inline system.

After the removal of the finished concrete blocks from the production board, five rotating disc brushes provide for fast and thorough elimination of residual concrete, dirt or rust. During the cleaning process, the manufacturing line is neither stopped nor is the production process slowed down. The cleaned boards are immediately available for the next production run.

At present, the Crust Cracker provides the highest cleaning performance of any inline cleaning system in the concrete block production industry, according to the manufacturer Weber Bürstensysteme. By developing the Crust Cracker, the company has designed an own machine for the first time, supported by CAD/CAM technology, engineers, mechanics and partners of the concrete block production industry. The result is a new and cost-effective solution, saving time and resources in the production of concrete blocks.