Concrete construction concept – Summer and winter

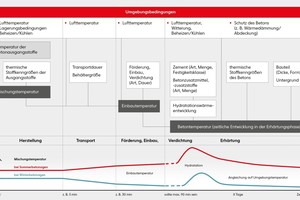

The concrete construction concept ensures the quality of concrete construction at ambient temperatures in summer and winter (< +5 °C; > +30 °C). Additional measures are taken, for example, to avoid structural damage due to freezing of the green concrete in winter, or high restraint stresses of the concrete building elements in summer. The concrete construction concept intervenes in all areas from concrete mix design to protecting and curing the green concrete. It also allows for a quality management plan to be drawn up with respect to, for example, the extended demolding and curing times at low temperatures and the storage of equipment and auxiliary building materials. Prior to construction, the contractor should agree summer and winter mix designs, related delivery temperatures and replacement supplier plants with the concrete manufacturer.

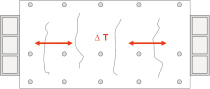

A high potential for cracks due to restraint action occurs when the concrete cools down again after the initial heating phase (cf. Fig.) and the related shortening process is impeded. If the resulting restraint stresses exceed the tensile strength, or shortening exceeds the elasticity of the hardening concrete, separation cracking occurs that traverses the entire concrete cross section. The determining factors are the development of heat during hydration, the cement content, the r-value of the concrete, and the dissipation of heat via the concrete surface to the environment. A higher concrete tensile strength at the time of hydration heat dissipation results in a higher amount of reinforcement when designing for “early restraint” while limiting the crack width.

In practical application, the potential for cracks resulting from thermal stresses can be reduced as follows:

Limiting the maximum temperature of the concrete in the first days

Reducing the difference in temperature between the building element core and building element fringe zone

Controlling heat dissipation