Blue-Yellow Eagle for efficient installation of paving units

In the German city of Sindelfingen, construction of a new car park that extends over seven levels was recently completed. The company Verbu-Bau GmbH of Heinsberg, Germany, specializes in installation of large pavements and uses low-emission machines for mechanical laying of the paving units. These ensure rapid work progress as well as protection of the health of laying equipment operators.

The new car park was scheduled to provide 4,000 additional parking spaces already this summer for the employees and the customers of a Stuttgart company. For Verbu-Bau, this meant that a total area of 16,000 m² would have to be paved within a few weeks’ time. “A first-rate joint pattern and smooth workflows were only two of several requirements that the client expected of us and our work,” said Ralf Terporten, Business Manager at Verbu-Bau GmbH.

At the end of April 2016, the teams from Verbu-Bau GmbH began paving the car park. It soon became evident that the existing laying equipment quickly reached its limits for the tasks required: it was not able to create sufficient clamping force to enable it to carry the heavy paving units. The block clusters sagged when being lifted, making proper laying simply impossible.

Combination of carrier vehicle and attachment unit

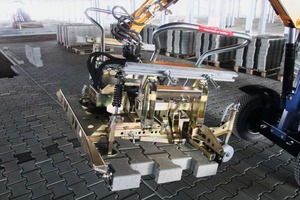

Since Verbu-Bau had several times in the past already worked with Probst with good results, the company contacted the Swabian machine builder directly. They quickly decided on the VM-301-K-Pavermax laying machine, called the Blue-Yellow Eagle, equipped with the hydraulic laying clamp HVZ-Uni-II as the best solution. Probst’s headquarters is located practically in the neighborhood, so that the Blue-Yellow Eagle could be transported to the construction site within a very short time. The combination of carrier vehicle and attachment unit ensures clean and rapid laying of the paving blocks.

The situation at the construction site was difficult, because the car park is supported by dozens of columns that impede access during laying; in addition, a clearance height of only 2 m had to be ensured. Here, the compact design of the VM-301-K-Pavermax was of additional advantage. The laying machine, including the clamp, can be easily maneuvered in a confined space and offers unrestricted all-around visibility, which considerably contributes to a smooth workflow. The block layers, moreover, can be easily and simply picked off directly from the pallets below the low beams.

In addition, the laying machine from Probst is equipped with a diesel particle filter that protects workers from inhaling harmful dust particles. Older machines can also be subsequently upgraded with a diesel particle filter. At a separation rate of more than 97 % of all particles, the filter satisfies the requirements of the Technical Rules for Hazardous Substances (TRGS 554), and is therefore the preferred choice for use in underground garages, halls, or other buildings.“ Our client was also positively surprised that not only the economic effectiveness has priority for us, but that also the health of our employees is of paramount importance,” reports Terporten.

For all standard commercial interlocking block clusters

The laying machine is part of the mechanical block laying process. But the superstar and friend in need at the Sindel-fingen construction site was the hydraulically operated laying clamp HVZ-Uni-II. At the construction site, only one laying machine with clamp was used – fully sufficient and effective for this area and for continuous daily use. The new laying clamp from Probst is universally suited for laying all standard commercially available interlocking block clusters, especially where speed and precise work are of the essence.

Laying heavy block layers is likewise child’s play, and the great clamping force – adjustable via a spindle – makes sagging block layers a thing of the past. The laying clamp hangs extremely steady – also during rapid machine movements – and reverberates only slightly, which allows very fast and efficient laying. If workers had previously handled block layers of only 1.0 m width, instead of the customary 1.2 m, they first had to tediously attach a shorter clamp. With the HVZ-Uni-II from Probst, only the grade-side outer lamellas and an adaptor had to be disassembled.

The HVZ slide force for lateral tension is three times that of conventional laying clamps. In order to adjust the clamp easily without wandering, also when lying on one block layer, vertical adjustment on the front grade side is now fitted with steel support plates and telescopic guide that cannot rotate as not desired.

Many challenges mastered

Another challenge posed by the installation of the pavers in Sindelfingen was laying interlocking paving blocks 10 cm thick. The installation of these blocks often requires manual correction of the installed block layer by means of a rubber hammer. This, thanks to the automatic push-out device in the Probst clamp, ADV for short, is now unnecessary. The clamps are now pushed with greater force into the ground and therefore no longer tilt from the horizontal. The tight schedule could be met despite the somewhat difficult conditions and the many obstacles the company had to overcome in laying the pavement.

“We focus on good quality and here, Probst is simply the right address. Top technology, good customer service, and Swabian reliability have convinced us 100 %,” summarizes Terporten.