Belgian company with long tradition invests in a new hollow core factory

Van Thuyne manufactures hollow core slabs, filigree slabs and pre-stressed filigree slabs, wall elements, pillars and girders. The decision to construct a new hollow core slab production was the initial step towards a general modernization process and an increase in capacities by 60 %.

The company Van Thuyne from Waregem, Belgium, can look back on a long and successful history. Founded in 1880 as a company in the building materials trade, the firm, which is headed today by the owners Tom Eeckhout and his wife, Fien Barra, quickly developed into a successful producer of precast concrete elements, which are held in high esteem not only in Belgium, but also in the Netherlands and France.

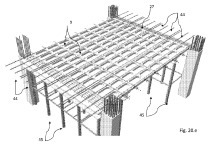

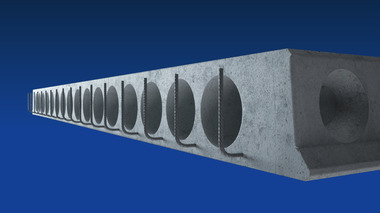

More than 60 employees cover a wide range of precast concrete elements, starting with hollow core slabs with a thickness of up to 500 mm, through pre-stressed filigree slabs 1.2 and 2.5 m (reinforced) wide, up to wall elements, pillars and girders.

Doubling of pre-stressed concrete production

The recent decision to construct a new hollow core slab production was Van Thuyne‘s initial step towards a general modernization process and an increase in production capacities by 60% to a total of twelve beds, each 160 m in size.

Thanks to this significant increase in production capacities to up to 2,300 m² of hollow core slab per day, Managing Director Tom Eeckhout feels well-equipped for the future. „The demand for hollow core slabs has increased considerably. We want to use this development for further growth in our company and therefore we decided to expand our capacities and to modernize our production machines.“

Two products with one production system

The hollow core slab production was extended in cooperation with the Belgian Echo Precast Engineering, one of the companies in the Progress Group and a leading machinery supplier for complete solutions in the precast concrete industry.

The core of the new production system is the Echo slip former. The S-Liner slip former is the ideal solution for versatile, flexible production requirements. As well as pre-stressed concrete filigree slabs, foundation piles, solid floors, joists, lintels, guttering, and even filigree slabs insulation and integral heating and cooling systems can be manufactured as required.

This versatility is made possible by the modular machine structure. Height differences in the same product series can be produced by quick, problem-free changing of the tube set and run-around. Changing to a completely different product can be completed even more quickly by replacing the production module. The specific construction of the S-Liner slip former and the use of dry concrete (zero slump concrete) make it exceptionally cost-efficient and easy to use and maintain. Each machine type can be configured for a track width/cutting width of 1.2 to 1.5 m or of 2.4 m.

In Van Thuyne‘s case the company decided on combined production of hollow core slabs and pre-stressed filigree slabs, 1.2 m wide, in order to offer flexible utilized capacity in production, adapted to the needs of the market.

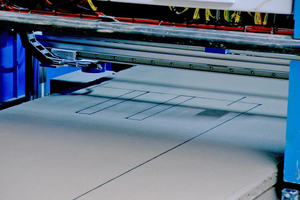

The highest precision with bed plotters

The automatic plotter from Echo Precast Engineering makes it possible to draw and print data such as cutting angles, project identifications and the area to be detached on precast concrete elements. Both the on top of the hollow core slabs and at the two sides of the precast concrete elements can be printed. The machine has an industrial PC. Data are transferred as a pxml file either via a USB storage medium or via a wireless network connection and controlled by special software prior to printing. Since the automatic plotter is battery-powered, no cables are required for production.

A multi-functional trolley, a concrete aspirator, a fresh concrete saw and a saw for cured concrete ensure efficient production preparation and a smooth production process.

The battery-powered multi-functional trolley, for instance, is used for the installation of new beds and has specialized rotary brushes to clean the production beds, wire-drawing equipment to draw the reinforcement wires and strands and a device for oiling the production beds.

The concrete aspirator removes concrete, which has not cured. It is used primarily to make cut outs for ducts, open cores, hammer heads, protruding reinforcement ends and cleaning of the tracks at the side of the casting bed.

Thanks to the fresh concrete saw and the saw for cured concrete the elements can be correctly cut to the required width and length at every stage of production. This saves time and costs and generally increases production flexibility.

Partnership for the future

The ambitious Van Thuyne group has recently succeeded in modernising its hollow core slab production. „We are very pleased,“ says Tom Eeckhout, „that we have undertaken this with a partner like Echo Precast Engineering, and we have very much appreciated their competence and assistance throughout the entire project.“

In addition, it was vital for van Thuyne to have a strong partnership based approach with a group such as the Progress Group for its further production modernization process; apart from setting up a new hollow core slab production, the company recently also completed a new carousel plant and modernized its steel processing: „Progress offers an all-round approach for the precast concrete industry. That was the deciding factor for us. As well as our new hollow core slab production we have, together with Ebawe Anlagentechnik GmbH and Progress Maschinen & Automation, also Progress Group companies, just completed a new carousel plant with a state-of-the-art shuttering robot. We are particularly proud of how well the reinforcement machinery integrates into this overall process, in particular the Wire Centre and the VGA Versa lattice girder welding machine.