BGC precast invests in battery mold for concrete precast-walls

BGC Precast, belonging to BGC Group and based in Kwinana, Western Australia, has invested in a battery mold from tecnocom, Italy, a company belonging to the PROGRESS GROUP, which is one of the leading groups in machinery and solutions for the concrete precast technology. The battery mold is producing noise-controlling wall panels, which are being installed on the North Link motorway, on to the outskirts of Perth in Western Australia.

BGC Precast manufactures high quality architectural and structural wall panels to client‘s requirements in their modern factory in Kwinana. They are well known for their reputation for high quality, and timely delivery.

Noise reduction walls are installed in numerous regions throughout Australia. As a lot of metropolitan communities are located alongside major roads, highways or railways road noise is a significant challenge for the government or developers to provide livable spaces. Precast concrete is the material of choice for many of these walls which are designed to reduce the transmission of noise. They either reflect the traffic sound in order to reduce the noise level that passes the barrier, or distribute it up- or downwards to dispersive the sound due to their incline or surface pattern. A third solution can be reached by using absorptive barriers, which absorb the sound by forcing the sound pressure waves to move in and around tiny fibers or passages to dissipate the sound energy. BGC Precast produces sound reflecting walls.

High quality, fast construction time

Precast noise walls offer advantages for the producers like being manufactured off-site in a controlled factory environment it is guaranteed to have a high quality product, which has excellent finishes and a fast construction time. Installation is simplified and safer as less working people are required on site. Beside that precast elements have countless options for striking designs including smooth off-form, stained or colored surfaces. Also patterns can be incorporated by using form liners.

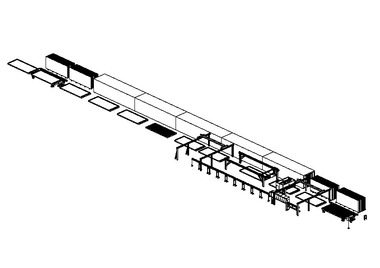

BGC invested in the new production line with battery molds instead of using casting on tables in order to benefit from advantages given by this manufacturing process. These are: higher productivity in limited space; excellent quality and finish of the elements; possibility to adjust the size using intermediate shutters and cast 2 walls each cell; possibility to use the battery mold also for other applications in the future, like partition walls for residential building, etc.

Fast delivery and installation They are the first company to use this kind of equipment in Western Australia. tecnocom could support the installation with short delivery and installation time as well as providing knowledge transfer given by specialists who trained BGC in tuning of the concrete mix to be used. With a battery mold BGC is able to produce up to 20 panels, as the battery, which contains ten cells is able to handle two panels per cell.

Phil Surridge, Business Development Manager at BGC Precast, takes up the story “The decision to use a battery mold from tecnocom was taken, after we had visited a reference customer in Abu Dhabi, who has a similar plant in operation. The quality of the technology that we saw there had convinced us to use it as well as the fact that tecnocom’s ability to meet an extremely tight production deadline.”