Adidas Halftime: Team of walls supports

roof network

A canteen of distinctive sculptural design has been built on the campus of sporting equipment manufacturer Adidas based in the German town of Herzogenaurach. The idea for the building was developed by Danish architects Cobe in cooperation with Knippershelbig consulting engineers. The complete version of this article (German only) appeared in the BetonBauteile Jahrbuch 2022 available from Bauverlag’s Profil bookstore.

An excursion to the “World of Sports” in Herzogenaurach has recently become worthwhile not only for those interested in sports but also for architecture enthusiasts. The Adidas headquarters in the so-called “Herzo Base” near Nuremberg have been continuously expanded over many years with buildings of outstanding architectural designs. An eye-catcher is the “Halftime” building based on a design by Danish architectural office Cobe. A rhomboid roof structure of precast concrete elements rests on precast walls of exposed concrete. The dark gray pigmentation of the walls creates the impression that the light-colored roof structure is floating several meters above the ground.

Adidas and architecture

Receiving 1.2 million job applications annually, Adidas is the most attractive employer among the DAX corporations. As such, the sporting equipment manufacturer wishes to offer its staff an inspiring work environment at the headquarters location that promotes the three “C” values: confidence, collaboration, creativity. The competitive tender for the Halftime building states that “central business units are based in this campus-style facility, which is given a distinct character due to its diversity of converted barrack buildings, high-end new construction, and a park-like open space interspersed with sports facilities.”

Against the backdrop of the company’s continuous growth, Adidas developed an urban design master plan for the campus, a central element of which is the building tendered under the working title of “Meet & Eat”. The design submitted by joint venture Cobe & CL MAP won the 1st prize. Experienced engineering office knippershelbig was commissioned with the structural design.

Meet, eat & showroom

A usable floor space of 15,500 m² is available under the rhomboid roof made of precast concrete beams. It includes a restaurant offering various food concepts, a bakery, and meeting rooms for the Adidas staff, as well as 7,000 m² of presentation space in the showroom for brand ambassadors. When designing the meeting rooms, the requirements of Adidas for workshops and meetings were assigned to different types of sport. This resulted in twelve rooms representing various sports facilities, a locker room, a swimming pool, a ski slope, or Adi Dassler’s shoemaking workshop. The multipurpose hall can accommodate 1,500 persons and is equipped with wall bars similar to those found in a gymnasium.

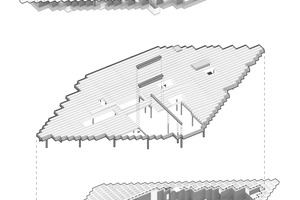

Rhomboid roof as design theme

The basic concept of combining the different required functions under a single rhomboid roof characterized the entire project from design to realization. The sense of space in the interior is defined by the visibility of the construction: exposed concrete walls or floor-to-ceiling windows, a concrete floor under one’s feet that is esthetic as well as functional, and skylights providing light from above. Looking at the building from the east or west, one is seeing a predominantly closed, dark structure. To the north and south, windows without parapets offer open, translucent views into and out of the building – interrupted only by the wall faces. The individual walls form a team and collectively support the roof, both in a structural and a metaphorical sense.

Design and structural framework

The building design comprises an outer “ring structure” that encloses the inner roof structure, a grid of main beams and secondary beams. The inner and outer supporting structures, on the other hand, have an independent design. The rhomboid grid covers the entire floor plan, projecting up to 9 m beyond the exterior walls. The cantilever beams are connected to the adjacent secondary beams by means of transverse bulkheads. The roof space covers 8,650 m², one third of which is occupied by skylights, so that there is no excessive heat input but the entire building is still evenly flooded with daylight. The roof structure comprises 3.2 km of precast concrete beams, the so-called “V-beams”, each with a 2-m high concrete cross-section, a weight of up to 28 t and standard spans of up to 16 m.

The main beams of the inner roof structure run orthogonal to the rigidly restrained precast concrete walls and are supported in the interior on up to 7-m high cantilever columns and wall slabs. Bracing is effected by means of restrained precast concrete columns, the core and cantilever walls, as well as the ring walls of the ring structure. The engineering firm responsible for designing the structure explains that “the characteristic V-shaped beams of reinforced concrete are the result of integrating a multitude of intermeshing design parameters, which include the structural design, natural lighting of the interiors and solar heat input.”

A 3D FE model served as the basis for the structural design of the bracing components and main beams in accordance with the requirements of Eurocode 2. Eleven different detailed models were created to examine the geometric constraints of the roof structures. The concrete cross-sections were designed with the most uniform possible distribution of reinforcement using the 3D FE detailed models. A C50/60 grade concrete was used for all of the V-beams.

In addition to the structural development of the detail solutions for the precast structure and verifications of the load-bearing capacities, the focus of the design was placed on the serviceability of the structure. The slender façade, which has in part been designed at right angles, connects to the structural framework of the inner roof structure. Incorporating and predicting the occurrence of deformations was essential to the design process. For this purpose, knippershelbig consulting engineers carried out 3D FE calculations based on a non-linear material behavior. Effects relevant to the construction phase and to the type and times of installation supports were predefined for the implementation of the design.

Progress of construction due to the type of construction

The decision in favor of precast concrete construction was made early on in the design stage in order to realize the highest possible quality standards for the color scheme, the surface finish, and the connection details of the exposed concrete beams and walls. “Prefabrication makes it possible to achieve a very high quality in terms of both concrete and detailing,” explains Ulrich Pohl, who was in charge of the detailed design at Cobe. Max Bögl Foundation took care of the precast concrete element design, produced the components at the factory and carried out installation. Realizing the main beams and columns as precast concrete elements made it possible to significantly reduce the construction time.

Max Bögl submitted the proposal to realize the project using precast concrete elements so as to allow the overall structural parameters of this type of construction to be closely coordinated with both the detailed design and structural design. Designing with precast concrete elements focuses on the connection and joining details, taking into account the design, technical and building-related constraints. It is advisable to decide on a type of construction at an early stage, as it will otherwise be necessary to adjust the structural system or even redesign the entire structure.

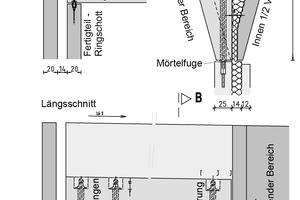

The main beams and secondary beams were transported to the construction site as precast elements. In areas where the beam joints need to withstand tensile stress, they were bolted together using Peikko wall shoes. In the area of the building envelope, the V-beams are composed of two interconnected elements separated by thermal insulation, each of which constitutes a V-leg.

The bracing precast concrete walls are rigidly restrained in the foundation. The designers used bolted connections for precast structures from Peikko to connect the precast walls and columns to the foundation and in wall joints where the walls were installed on top of each other. The non-load-bearing wall slab of the sandwich walls installed in the area of the exterior walls was placed on the inside in order to support the V-beams of the outer roof structure on the load-bearing outer wall slab. Mechanical column connectors in the wall and column joints absorb high shear forces. HPKM column shoes were cast into the concrete walls at the Max Bögl precast plant and were then connected to the foundation by means of HPM anchor bolts. Column shoes require less space and are therefore an alternative to wall shoes for use in slender wall elements in order to prevent collisions in the reinforcement.

Certified, award-winning, popular

The building is extremely energy-efficient and has zero primary energy demand – it was awarded the LEED Gold certification for sustainable construction. It did not take long for the award-winning architecture to receive recognition: in 2015, the Halftime building won the Iconic Award for visionary architecture. For the orientation system, EIGA Design and Cobe were awarded the Red Dot Design Award for Brands and Communication Design in 2019. In 2020, the building was a finalist in the ArchDaily Building of the Year Award and was on the longlist of Dezeen Awards.

Since completion of the multipurpose hall, the ingeniously designed rooms have been promoting both the quality of meetings and the creativity of the staff. The premises offer the entire “Adidas family” ample space for joint (“halftime”) breaks, creative workshops, product presentations, meetings and numerous other event formats. The popularity is such that the rooms, which are only available for internal use, have to be booked well in advance. The attractive architectural design of the corporate headquarters contributes to further establishing the Adidas name as one of the most sought-after employers.