A universal computation and design tool

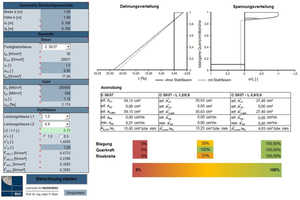

A comprehensive computation and design tool for rectangular cross-sections made from steel-fiber-reinforced concrete and concrete reinforced with both steel rebar and fibers was developed using spreadsheets and optimization methods. This project started from the specifications contained in the officially introduced DAfStb (German Committee for Structural Concrete) guideline on steel-fiber-reinforced concrete as well as in DIN EN 1992-1-1 (Eurocode 2) with respect to conventional concrete structures, such as in building construction.

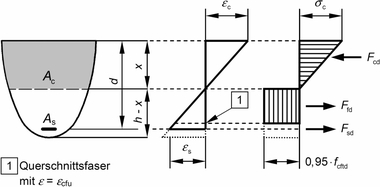

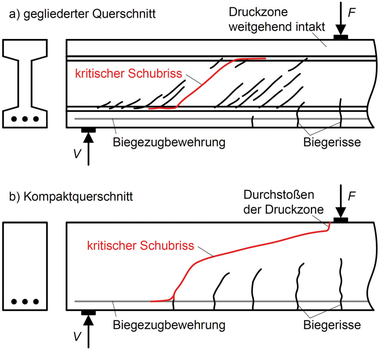

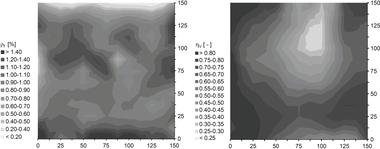

In the first step, the program computes internal forces according to the yield line theory and/or the DBV Code of Practice on “Industrial Floors made from Steel-Fiber-Reinforced Concrete” for bedded slabs under various point or area load configurations. Only such non-linear methods of determining internal forces succeed in defining cost-effective designs with integrated fibers [2]. The actual cross-sectional design includes the usual predictive dimensioning in the ultimate limit state (bending, combined bending and axial load, shear) and in the serviceability limit state (crack control, limitation of stresses). The relevant minimum reinforcement ratios are checked. Furthermore, the program enables reverse computations, for instance to identify the fiber classes required for reinforcement ratios specified for defined strain or load scenarios. These computations are supported by options for optimizing performance classes. Results are visualized for cross-sections and degrees of utilization and contrasted quantitatively with types of concrete reinforced exclusively with steel rebar.

Gradient methods (GRG) are applied to solve the equation; stress integrals are solved analytically [3]. For stability reasons, automatically repeated iterative loops with varying starting values were implemented [1]. They begin at the definition boundaries of permissible elongations and sub-divide the possible elongation value solution space for the iterations. Standard computers require only a few seconds to complete this computation.