3D-printed reinforced-concrete elements

Additive manufacture (AM) and/or 3D printing with concrete represents a highly innovative and future-oriented production technology for the construction industry. For one, linkage with modern information and communication technology results in automated production and, second, it enables production of a great variety of forms with high cost efficiency at the same time – even for the smallest quantities – of (steel-reinforced) concrete elements.

Most investigations currently focus on the concrete material itself (e.g., pumpability and green strength of the fresh concrete), on which a number of research results are already available. Investigations must be intensified, however, regarding integration of the required steel reinforcement in the printing process, as well as regarding the load-deformation behavior of the printed structural elements.

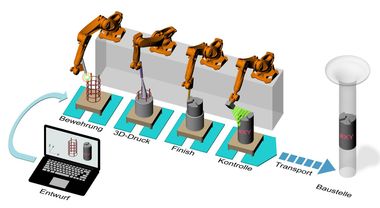

At the iBMB, Department of Concrete Structures at TU Braunschweig, Germany, in collaboration with the Institute for Structural Design (ITE) of TU Braunschweig, the first concrete columns with integrated steel-bar reinforcement were printed on the basis of SC3DP (Shotcrete 3D Printing) AM technology developed at ITE (Fig.). The 3D-printed reinforced-concrete columns were initially examined at the iBMB, Department of Concrete Structures, with regard to their precision of manufacture and integrity, and were then tested under longitudinal uniaxial excentric compression. Compared to a conventionally manufactured column (formwork and compacted concrete), comparable load-deformation behavior resulted; however, the 3D-printed reinforced-concrete columns evidenced a greater degree of spalling. Subsequent numeric analysis of the load-deformation behavior by non-linear framework analyses showed that the ultimate loads can be well predicted by taking into consideration the real dimensions of the structural elements, in accordance with the above-stated measured manufacturing precision.