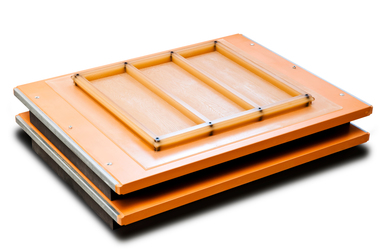

Wet-cast molds for

concrete slabs with a small contour width

Wet-cast slabs upgrade the garden in its visual appearance. They look like natural stone and are individually cast of concrete. They are suitable for terraces and pathways as well as retaining walls. Via Domo based in Allmendingen (Germany) designs the right molds for this purpose according to the individual customer requests. Special materials and innovative processes allow the manufacturer to reconstruct different surface textures in an especially filigree manner. The rise of the wet-cast technology started in England when completing balconies and terraces. Now, the wet-cast slabs made of...